Frequently Asked Questions

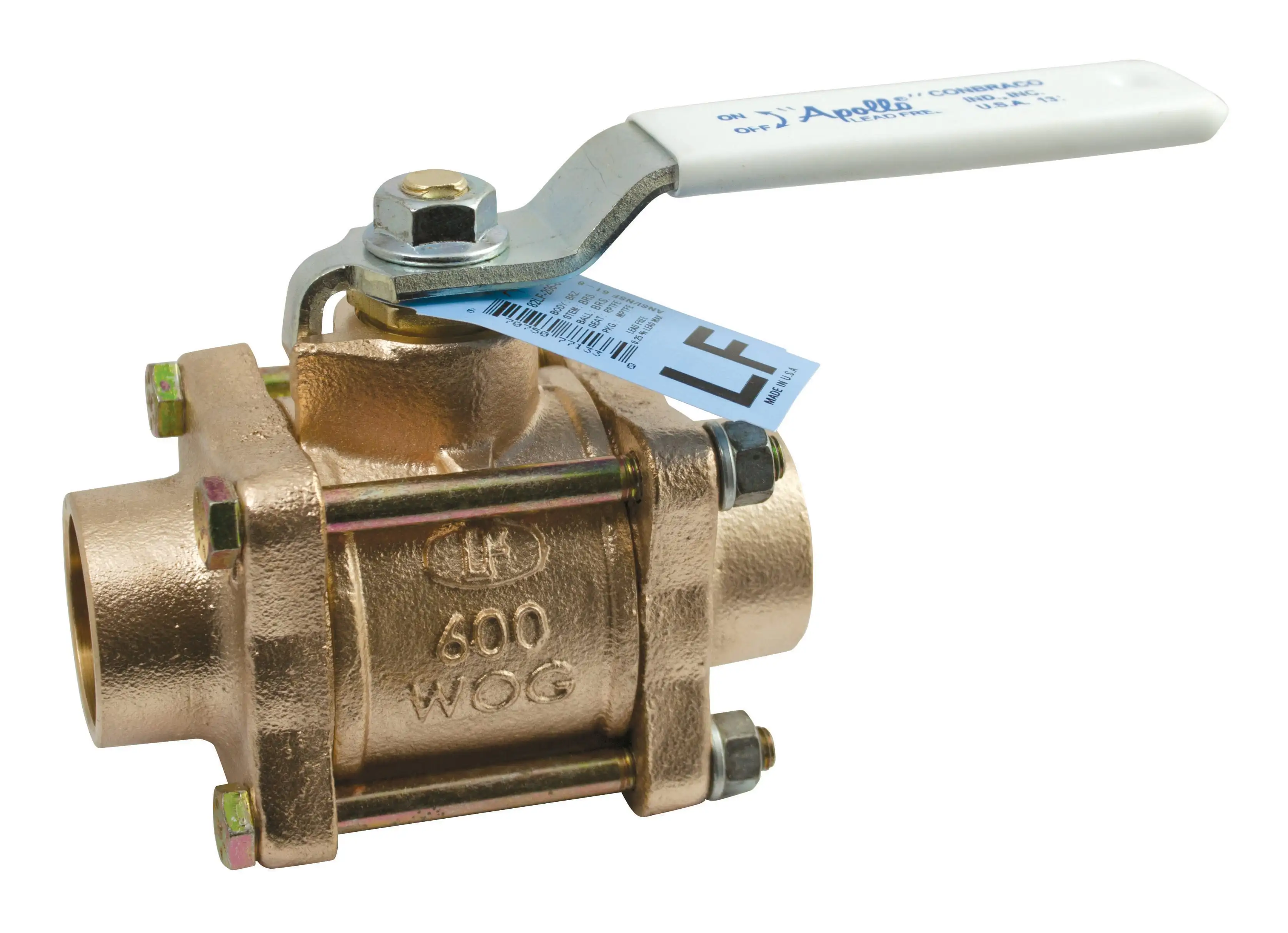

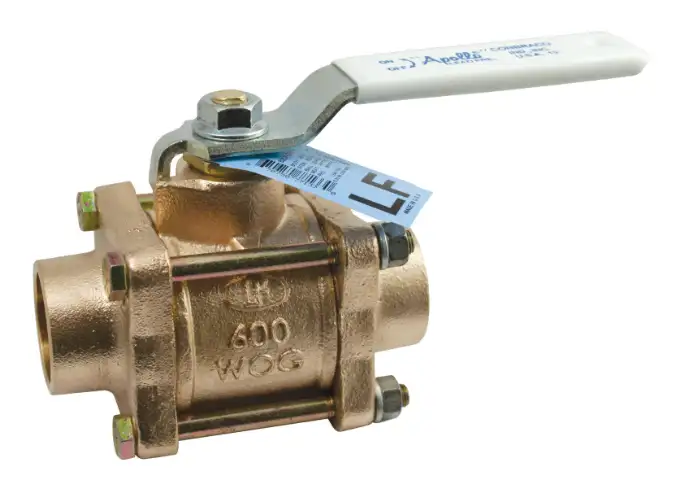

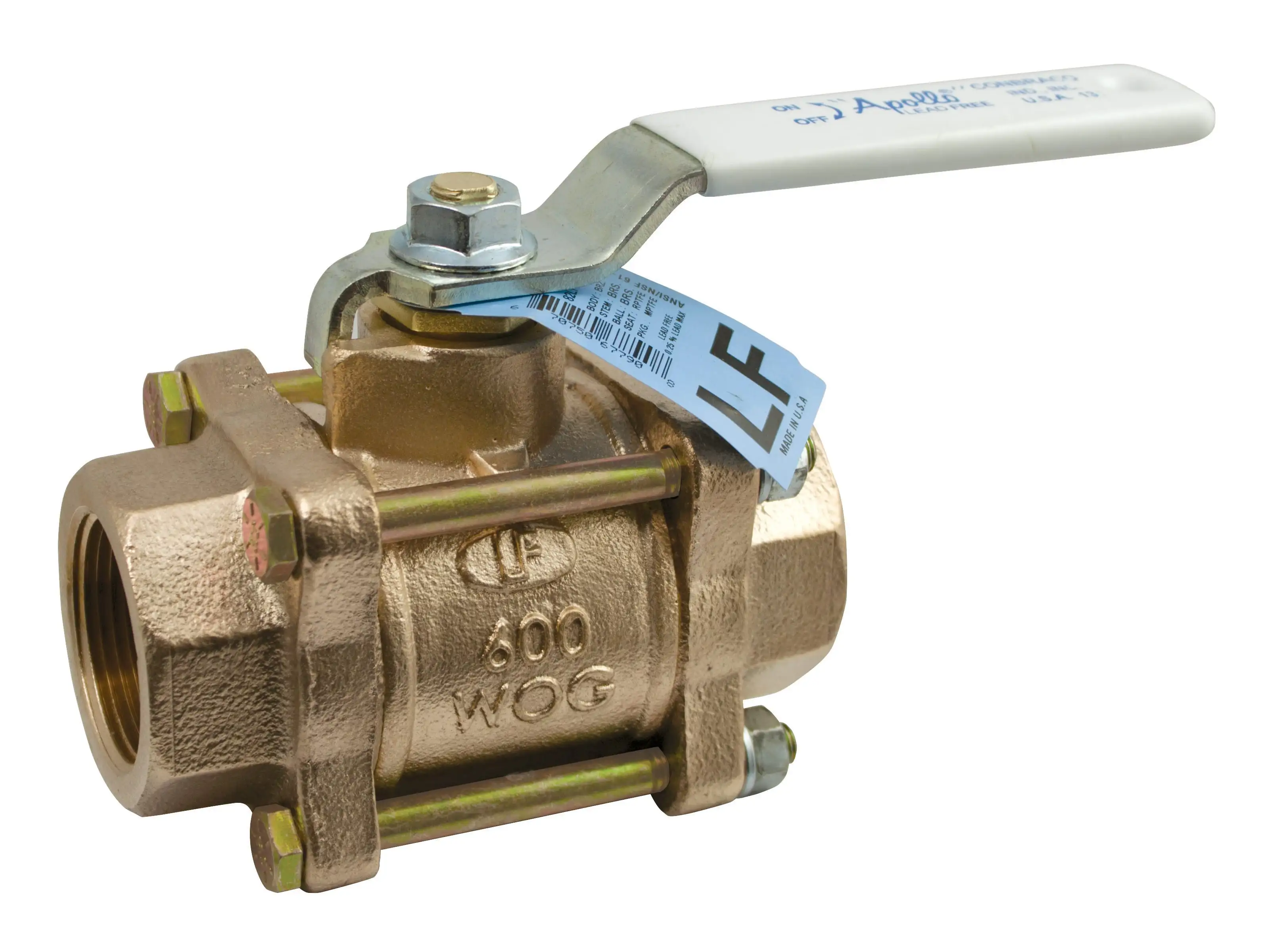

How to install a ball valve?

Insert the Apollo ball valve's input and output into your threaded assembly and screw them. Before installing the handle, make sure it is properly installed (parallel is open).

Are ball valves suitable for throttling applications?

While Apollo ball valves can be used for throttling, they are not as precise as other types of valves. So, if you want a valve only for throttling purposes, then you should go for Apollo globe valves.

Are the quarter-turn valve and ball valve the same thing?

A quarter-turn valve is not the same as a ball valve, but a ball valve is a type of quarter-turn valve. A quarter-turn valve is a general term for any valve that requires only a quarter-turn (90 degrees) of the valve handle or lever to move from fully closed to fully open or vice versa. So, while a ball valve is a type of quarter-turn valve, not all quarter-turn valves are ball valves.

What is the difference between a two-way and a three-way ball valve?

A two-way ball valve has only two ports and can only allow or disallow the flow. A three-way ball valve, on the other hand, has three ports and can be used to divert, mix or isolate flows from multiple directions.

How do I choose suitable ball valves for my application?

- Consider the appropriate valve size based on flow rate and your application requirements.

- Ensure the valve can withstand the maximum pressure required for the application.

- Select the proper end connections for compatibility with the piping system.

How do ball valves compare to other types of valves?

They provide better sealing, require less force to operate, have lower pressure drops and offer faster response times.

How can I maintain these ball valves?

Proper maintenance of ball valves involves periodic inspection, lubrication of seals & bearings and addressing any signs of leakage or damage.

£ GBPChange Country

£ GBPChange Country