Frequently Asked Questions

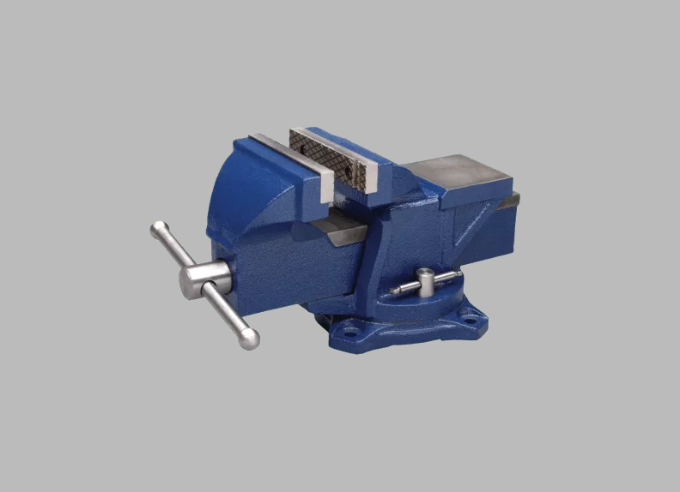

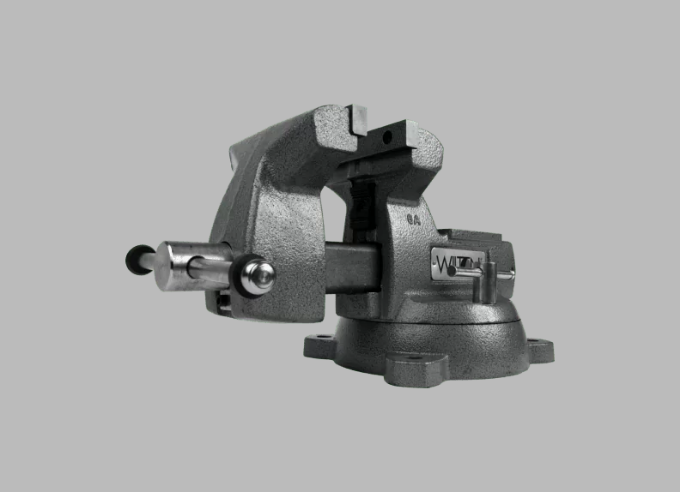

What is the construction material of Wilton bench vises?

Wilton bench vises are usually constructed of malleable cast iron or cast steel. The jaws of these bench vises are often detached and can be changed, usually carved with diamond or serrated teeth.

What are the advantages of using Wilton bench vises?

The major function of any vise is to hold an object securely and safely so that it can be worked on. Wilton bench vises make work, such as sanding, finishing, chipping, sawing and welding easier by freeing the user's hands to perform the required task.

What is the mechanism behind the working of a Wilton bench vise?

Vise is a device consisting of two parallel jaws for securing a workpiece. One of the jaws is fixed and the other is movable using a lever, screw or a cam. The vise can be bolted forever to a bench for holding a workpiece during operations, such as hammering, filing or sawing.

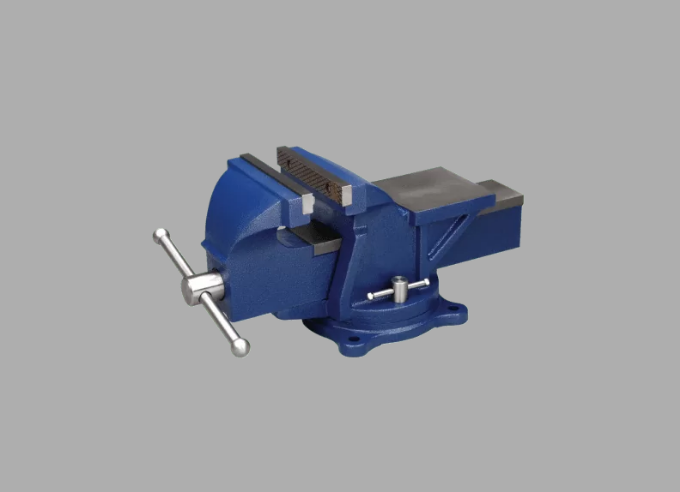

What does throat depth refer to in a bench vise?

Throat depth in a bench vise typically refers to the vertical distance from the top edge of the jaw to the top of the main guide rods and screws. For these vises, 3 to 4 inches is the ideal throat depth range.

Which type of thread is used in Wilton vises?

Buttress thread is usually used in a bench vise. In such a type of thread, one flank is perpendicular to the axis of the thread and another flank is angled at 45 degrees. These threads are employed in carpentry vises, bench vises, power press, gun breeches and ratchets.

What are the safety precautions to be considered while using bench vise?

Users need to cover their eyes and faces with a shield, safety glasses and goggles. They need to make sure that the bench vise fits perfectly to the work table with bolts. Users need to keep the fixed jaw at length slightly beyond the working table to keep the long pieces away from interfering.

How can we secure the finished surface in a vise?

Soft metal, wood or copper can be used to secure finishes from insert jaw serrations.

£ GBPChange Country

£ GBPChange Country