Frequently Asked Questions

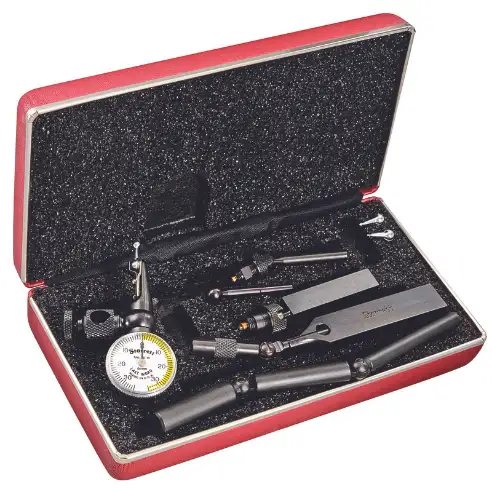

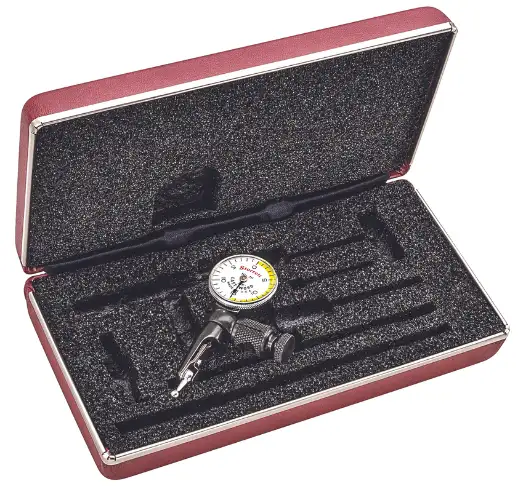

What is a dial drop indicator?

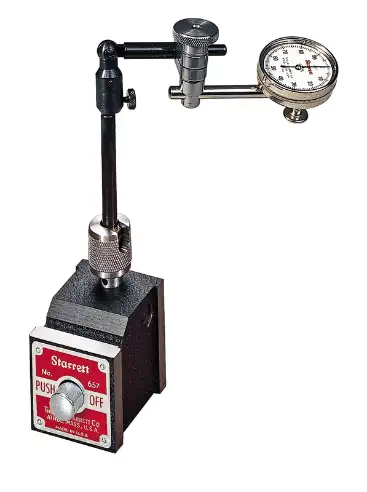

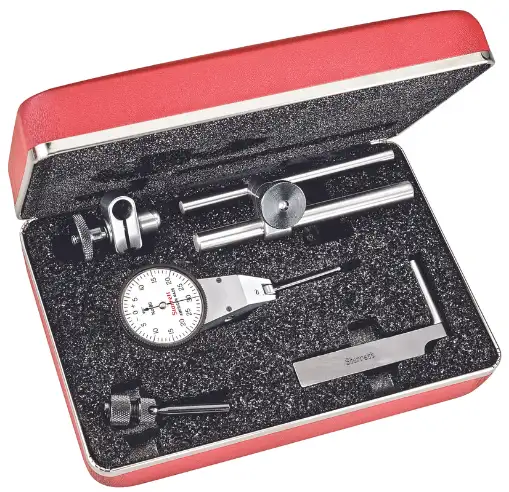

Starrett dial drop indicators, also known as plunger-style dial indicators, come with a dial face attached to a stem with a contact point on the end. When the contact point meets the workpiece, the up-and-down motion of the plunger is increased on the graduated dial face.

What are the different parts of a Starrett dial indicator?

Some of the major parts of dial indicators are a dial consolidated on the main scale, the plunger, locking screw or locknut, mini dial that indicates the number of revolutions and magnification mechanism.

What are the two basic types of dial indicators?

The two basic types of indicator dials are balanced and continuous. To use one or the other is usually decided by the gauge and the range of the indicator. However, in general, if the resistances are reciprocal, like +/- 0.001 inches, the balanced dial is used.

What kind of measurements are Starrett dial indicators employed for?

Starrett dial indicators are one of the main measuring tools used in precision engine building. These dial indicators are suitable for measuring crankshaft thrust, deck clearances and other measurements that need the distance between two surfaces.

How are Starrett dial indicators different from dial test indicators?

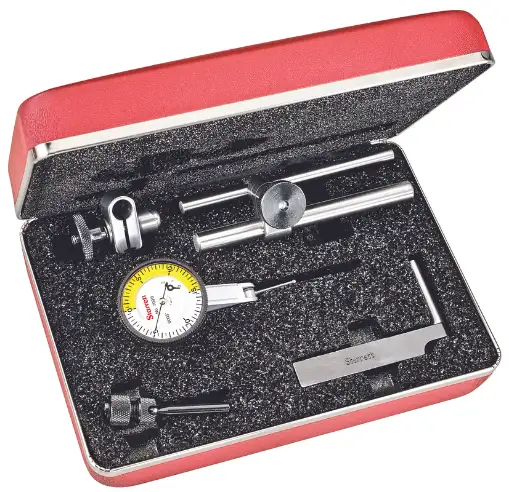

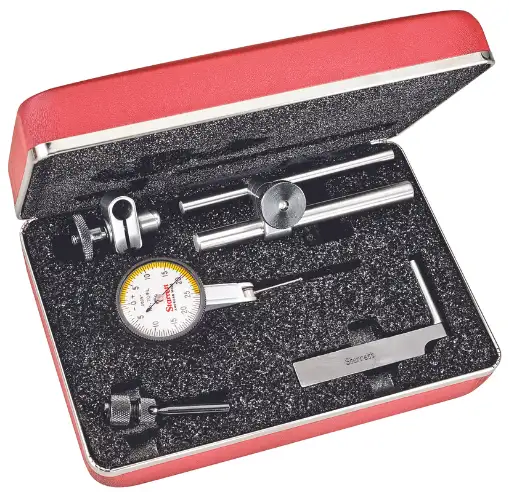

Starrett test indicators are quite distinct from dial indicators. The most notable difference is that dial indicators have plunger-type contacts. Whereas the test indicators feature lever-type contacts while they are also smaller and lighter in comparison to dial indicators.

Where are Starrett dial indicators manufactured?

Starrett has been manufacturing tools in the United States, having its headquarters in Athol, Massachusetts.

What is the range of dial indicators?

Starrett dial indicators usually range from 0.25 mm to 300 mm, with graduations of 0.001 mm to 0.01 mm (metric) or 0.00005 to 0.001 inches.

What are the guidelines for the proper use of Starrett dial indicators?

To make sure the indicator hand can move freely, it should be able to move to its total capacity and the zero ends of the scale in one fluid movement. Some of the guidelines are as follow

Do ensure you use your indicator correctly by securely affixing it to the holding device. Do use your dial indicator often to prevent the spindle from sticking.Do ensure you keep your dial indicators stored away correctly in a dry place and try to keep them covered to minimize dust and moisture getting into the dial.Clean the dial with hot soapy water and try to keep the dial clean and dry at all times. How do you adjust a Starrett dial indicator?

Lift the plunger and slip a 0.020-inch gauge block underneath. Drop the plunger onto the surface of the gauge block. Inspect that the indicator reads 0.020-inch. Then, lift and lower the plunger two more times to check that the dial indicator provides the same measurement in the exact spot constantly.

£ GBPChange Country

£ GBPChange Country