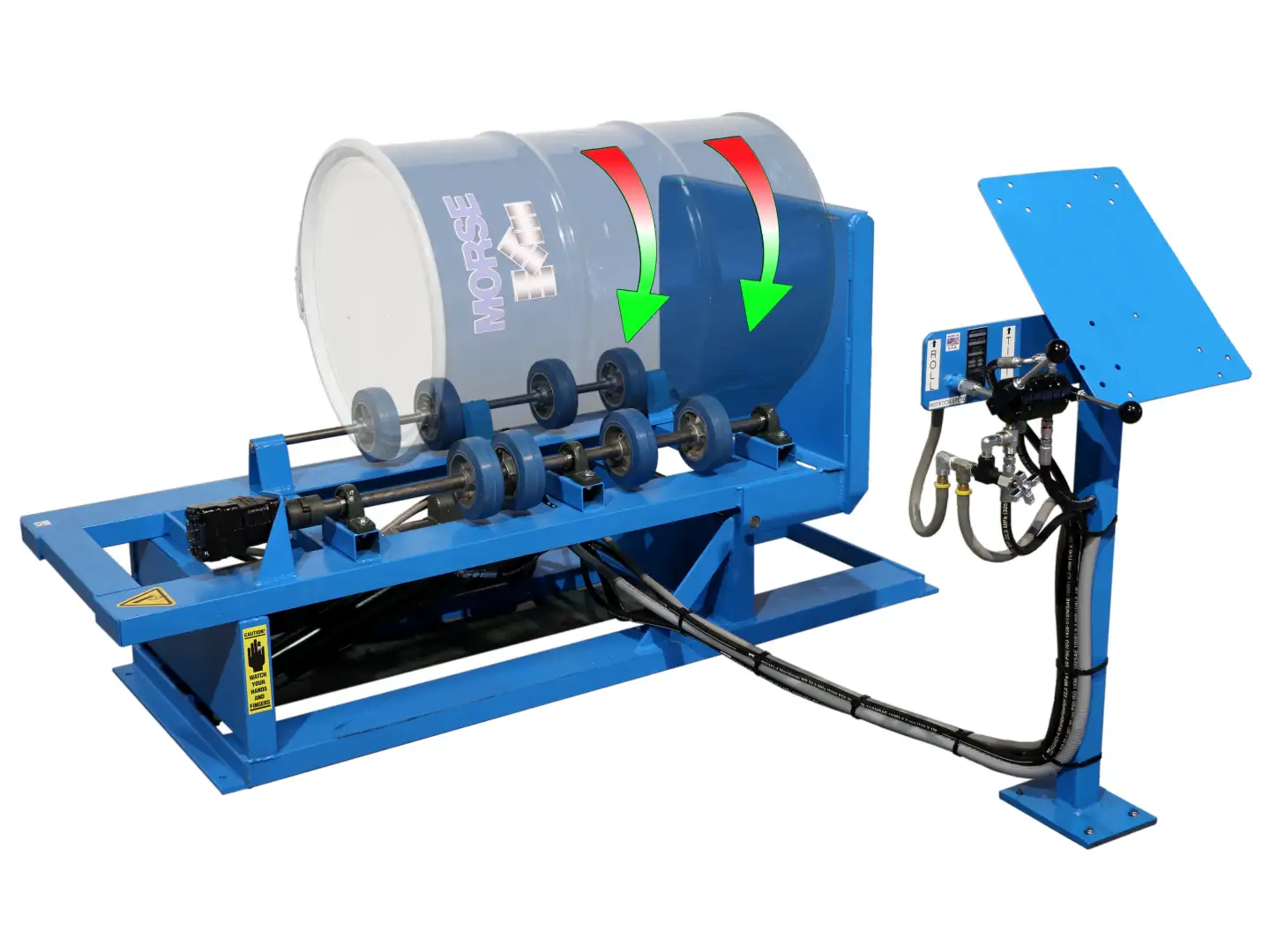

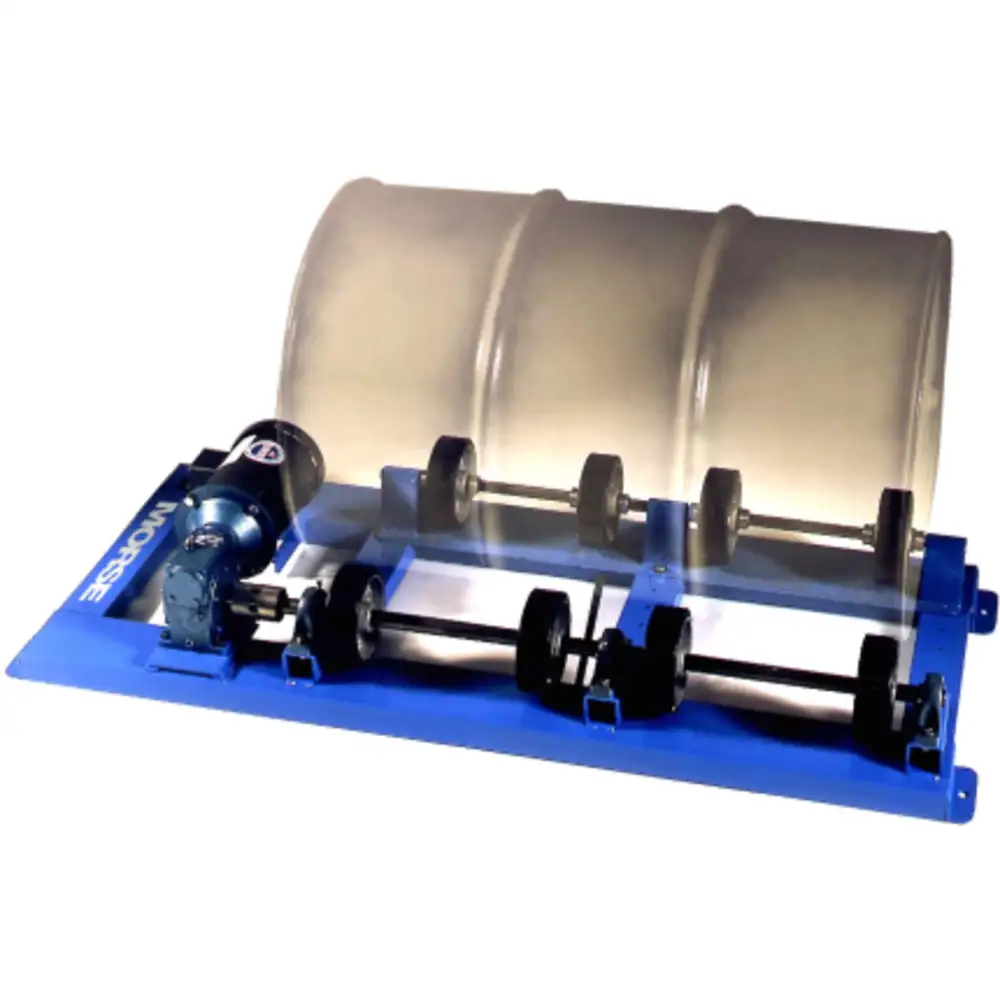

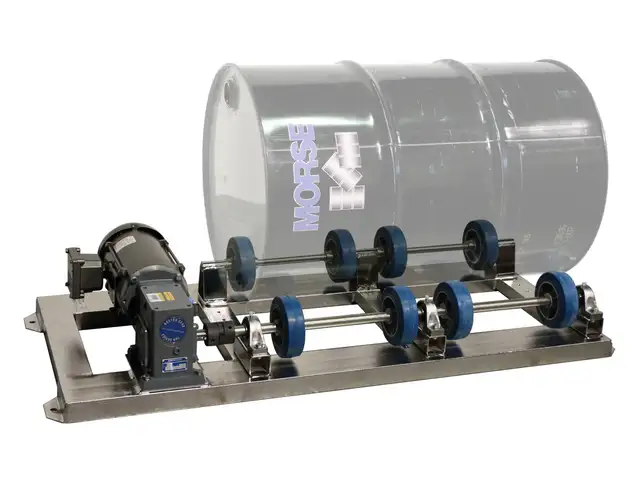

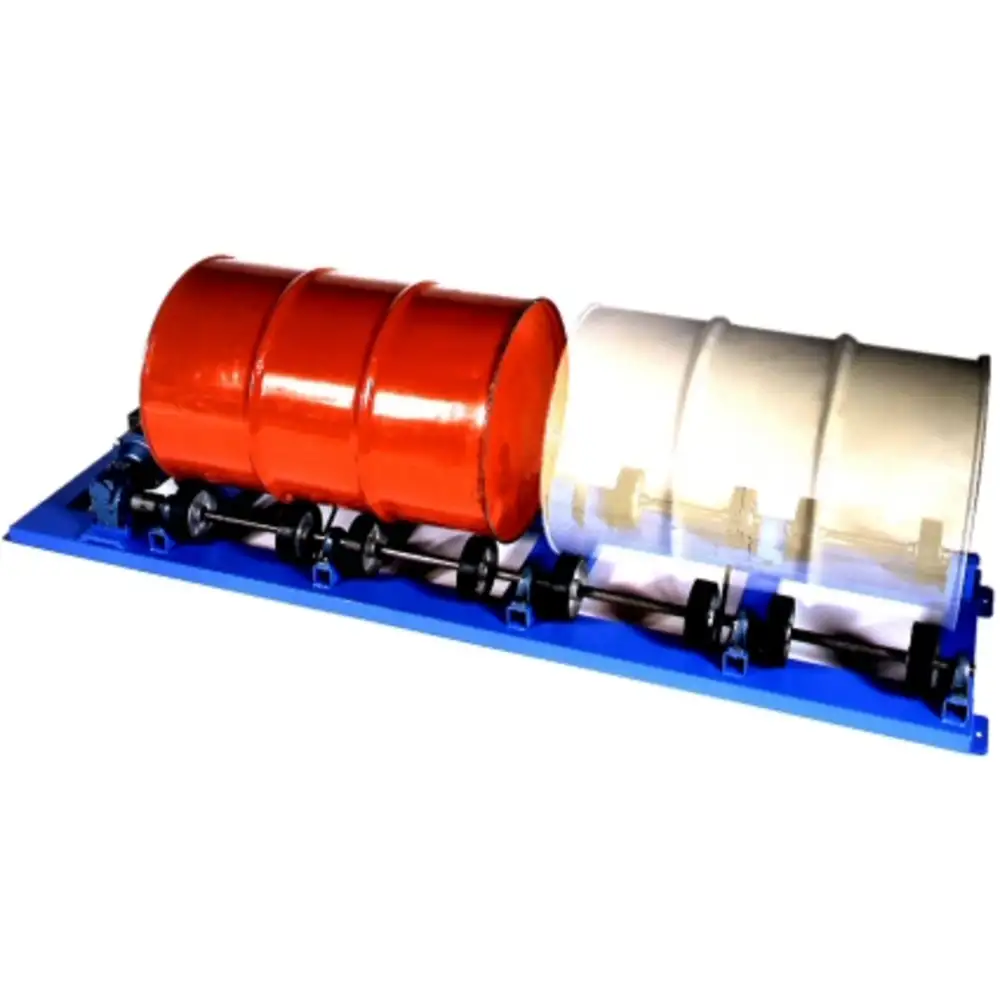

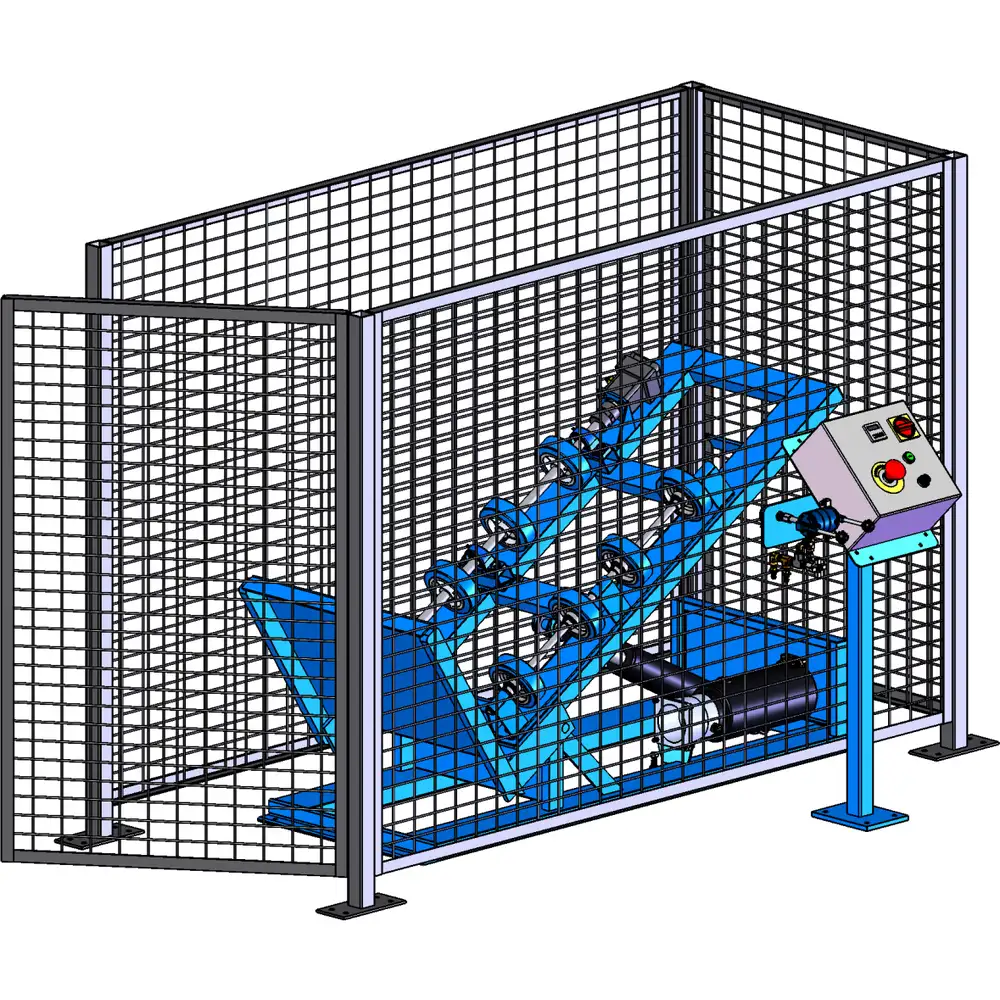

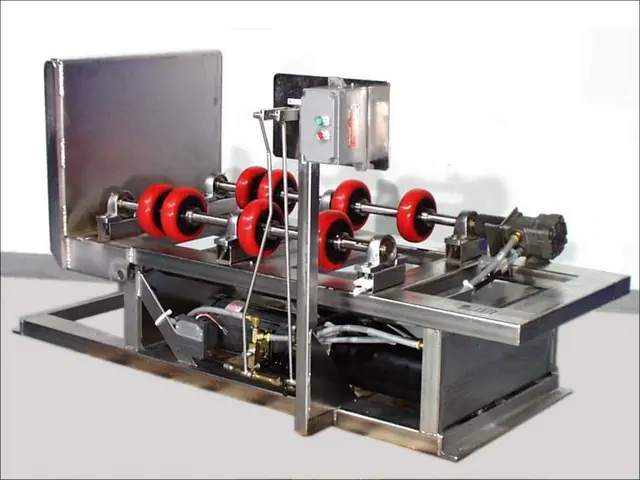

Morse Drum industrial-grade drum rollers are designed to accommodate 30 / 55 gallon drums containing paint, oil, glue, dye and resin and produce a homogeneous mixture at both fixed and variable speed settings. The Morse Drum 201 Series drum rollers feature enclosed back and sides to protect the drive mechanism and a built-in tipping bar with a new kickstand design for supporting the roller, for drum deployment, in upright position. These drum rollers also come equipped with 4 heavy-duty caster wheels for drum relocation or portability purposes. For providing a hands-free mixing operation, the Morse Drum 456 Series lift drum rollers feature a built-in hydraulic system that efficiently lifts the drum, kept at the floor level. Additionally, these rollers also offer variable drum rotating speed ranging from 5 to 20 RPM. Choose from a wide range of these drum rollers, available in single and three-phase motor variants on Raptor Supplies, an authorised Morse Drum distributor.

£ GBPChange Country

£ GBPChange Country