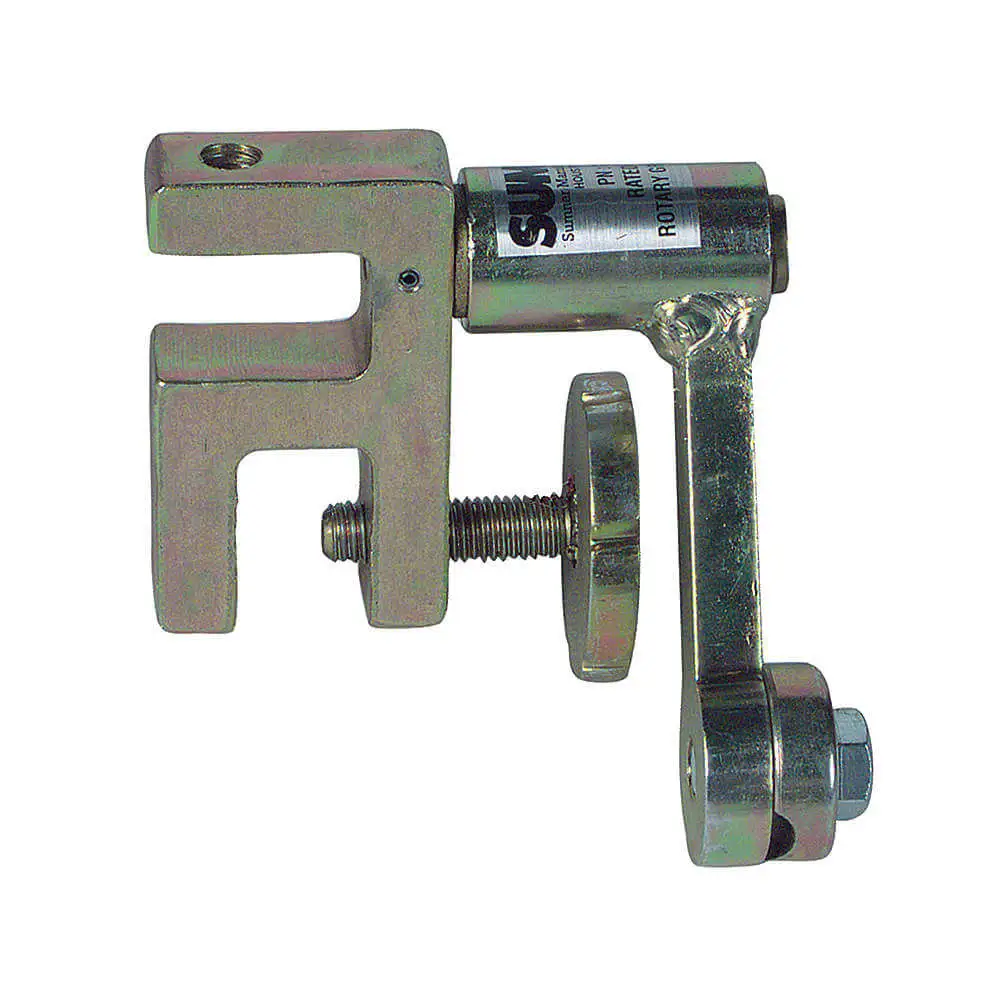

Jackson Safety Centering Heads:

- They help users in the setting of centre lines, establishing angles and marks.

- These centering heads have a spring-loaded hardened centring pin that eliminates the need for a hammer.

Jackson Safety Flange Aligning Tools:

- They have notches at either end for easy alignment with the pipe's centerline.

- These aligning tools include two 25-pound pull, cast-in magnets in horizontal or vertical positions.

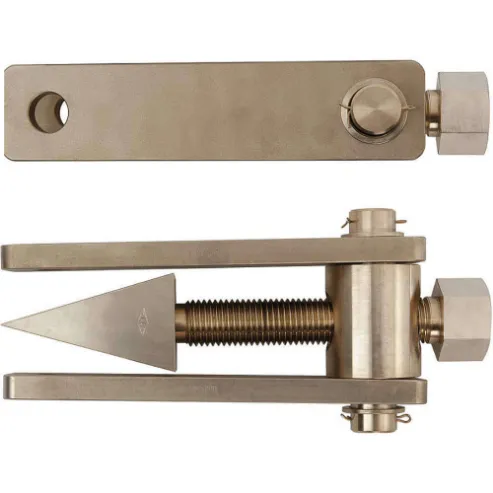

Sumner Flange Spreaders:

- Flange spreaders are used to spread the flange faces without damaging flange sealing surfaces.

- Their steel construction can withstand up to 1500 lb force.

£ GBPChange Country

£ GBPChange Country