Features

Low Pressure Filter Moduflow Plus Series hydraulic filter elements

- The patented Parker Moduflow Plus Series low pressure (in-line suction / return / duplex) hydraulic filter elements feature one piece element design with customisable bypass settings to prevent parts loosening and ensuring easier maintenance.

- These hydraulic filter elements have Microglass III / water removal media to offer 60% more surface area within the same filter housing than most of the comparable filters.

- Parker Moduflow Plus Series hydraulic filter elements provide more dirt holding capacity, ensuring less need for replacement as compared to conventional hydraulic filter elements.

- These hydraulic filter elements come equipped with nitrile seals to provide resistant sealing against petroleum oils, crude oil, water, gasoline and propane.

- Parker Moduflow Plus Series hydraulic filter elements offer flow rates up to 10 gpm and a maximum operating pressure of 200 psi.

CN Series hydraulic filter elements

- Parker CN Series hydraulic filter elements are recommended for applications in Off-line filter loops, automotive standard machine tools, hydrostatic drive charge pumps, mobile equipment, oil patch drilling equipment, pilot lines for servo controls and in Injection moulding.

- Parker CN Series hydraulic filter elements feature aluminium housing for protection from harmful UV radiations and fluorocarbon seal for low stretching & high abrasion resistance.

- Threse hydraulic filter elements have Microglass III media for filtering out contaminants easily.

- Parker CN Series hydraulic filter elements are equipped with a patented end cap to minimise turbulence and pressure loss.

- These hydraulic filter elements offer flow rates up to 80 GPM and a maximum operating pressure of 150 psi.

- CN series filters are offered with either conventional or ecoglass element.

- The eco glass elements feature an environmentally friendly design with no metal inner core to reduce the overall weight by 50%, thereby ensuring easy disposal of used hydraulic filter elements and lowering disposal costs.

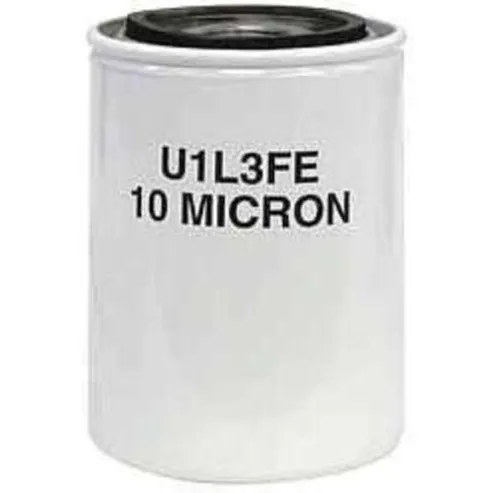

A wide range of these hydraulic filter elements are available in 10 & 20 micron variants on Raptor Supplies, a trusted Parker hydraulic filter elements Supplier.

Working Mechanism

As fluid flows through the filter element, dust particles or unwanted chemicals are trapped by the media. Simultaneously, the fluid develops a differential pressure between the inlet and outlet. The spring present in the hydraulic system holds the bypass piston and senses the pressure difference. As the differential pressure reaches a specific threshold, the indicator switches ON to indicate the need for cleaning or replacement. As the perforated protective cage around filter mats connects to the two end discs, it will allow the fluids to flow freely and continuously in the hydraulic filter element. Now, when the fluid flows through the mat, the protective cage will protect from any external damages. The attached seal rings or profile seals will seal the space between the filter element and filter housing, thus stopping or reducing the leakage occurring from the hydraulic filter element. As fluid continues flowing, more & more contaminants remain in hydraulic filter elements, and thus the clean hydraulic fluid will flow out through the outlet into the hydraulic system.

£ GBPChange Country

£ GBPChange Country