Uses

Machinery movers are used for lifting, moving, landing, assembling or erecting large & heavy machines or loads in the manufacturing, automobile, mining and food & beverage industries.

Features

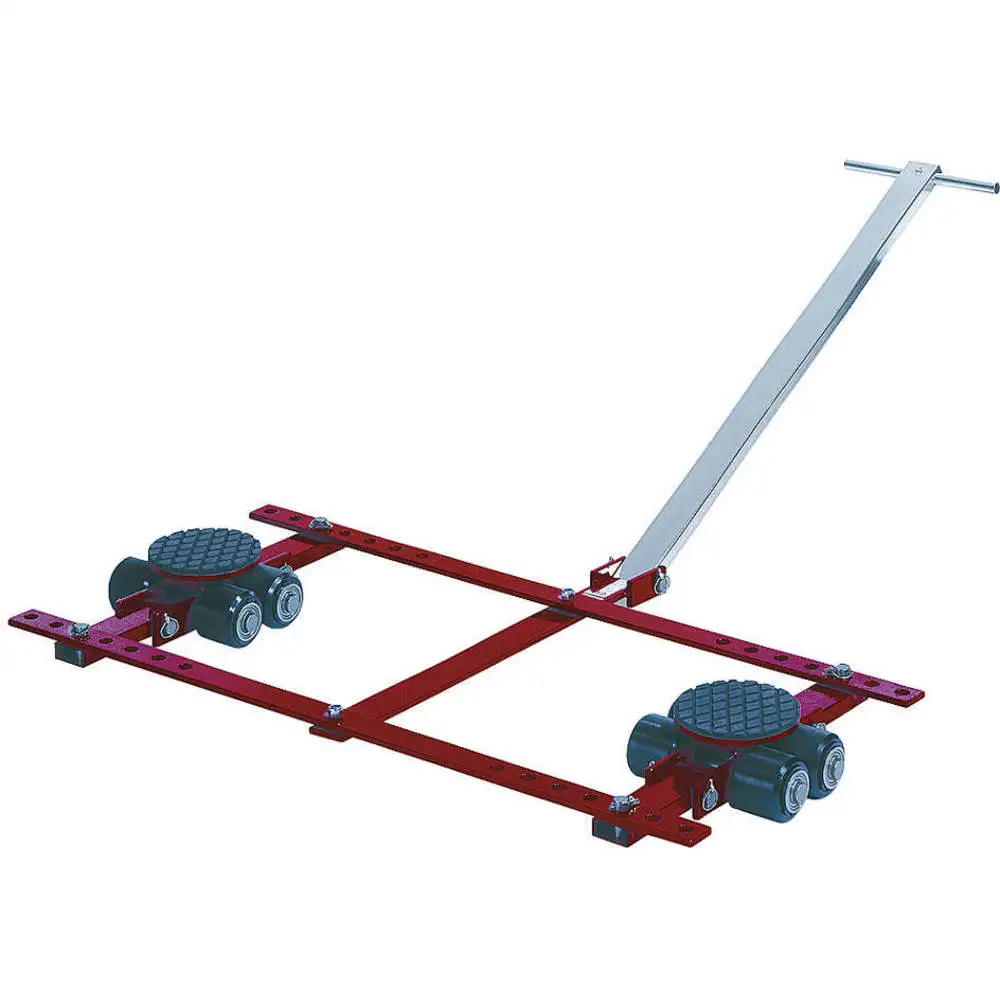

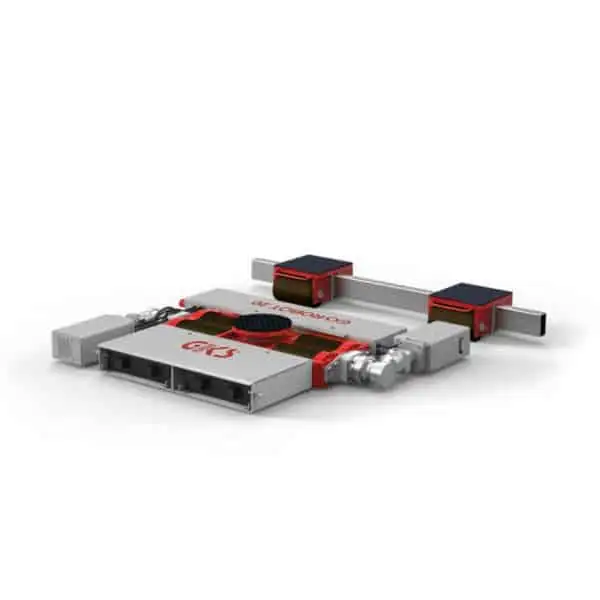

GKS-Perfekt machinery movers:

- machine dollies are used to move and position bulky & heavy loads over rough or smooth surfaces.

- These machinery movers feature heavy duty welded steel frames with powder coated finish to ensure excellent structural rigidity and load stability.

- These GKS-Perfekt machinery movers are equipped with rollers made of polyamide for high thermal and abrasion resistance.

- Low-profile loading height of these machinery movers allows for optimum versatility.

- These machinery movers have anti-slip pads on contact points for high load friction to ensure safe transporting.

- These GKS-Perfekt machinery movers also incorporate a pulling handle with tow eye for controlled turning and easy straight line movement.

- With a maximum load capacity of 132000 lb, these GKS-Perfekt machinery movers come with 8 casters for smooth mobility.

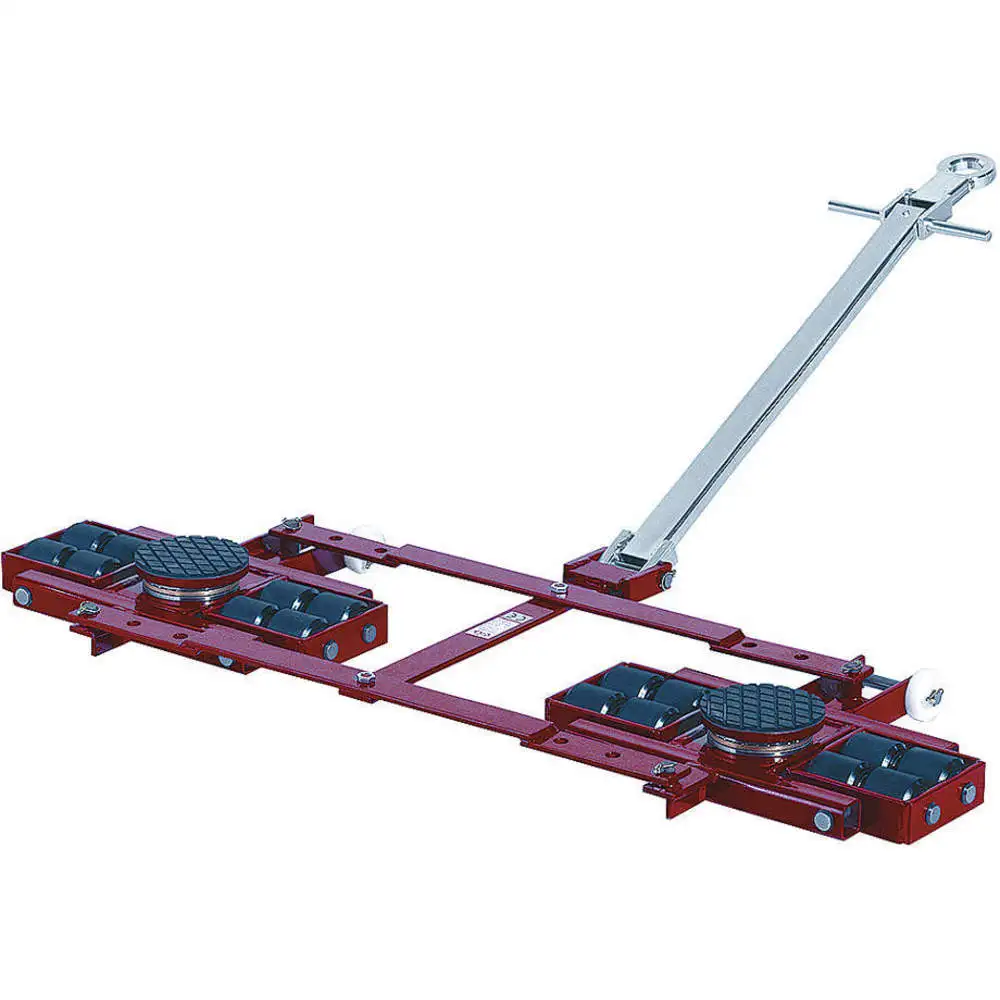

rotating machine dollies:

- Rotating machine dollies by GKS-Perfekt are suitable for narrow hallways, tight spaces & tricky corners and are manufactured to withstand loads up to 8800 lb.

- These GKS-Perfekt machinery movers are equipped with special bearings that enable a 360-degree swivel, making these machinery movers ideal for navigating the turns and twists of the facility floor.

- These machinery movers feature steel construction with powder coated finish for scratch resistance and have a textured rubber centre padding to provide a strong grip.

- GKS-Perfekt rotating machine dollies can be used in conjunction with at least two additional dollies, all working together for moving the loads to their destination.

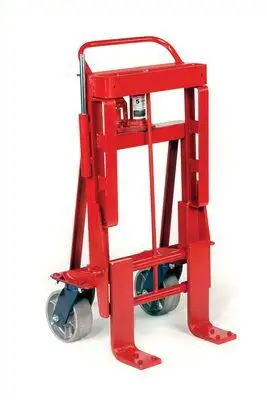

Vestil machinery movers:

- Vestil MFM Series machinery lifts are suitable for moving bulky and heavy loads that are difficult to position or move, such as furniture, refrigerators and industrial manufacturing machines.

- These machinery movers safely transport fragile and sensitive equipment like computers or glasses.

- Large wheels of Vestil MFM Series machinery movers allow smooth movement over cracks and bumps of factory floors.

- These machinery movers have an adjustable fork that allows precise positioning to accommodate loads of varying widths.

- Vestil MFM Series machinery movers come equipped with phenolic / steel / semi steel casters for vibration damping and excellent floor protection.

- With a maximum load capacity of 12000 lb, these Vestil machinery movers are available with optional side straps to secure loads for stable movement.

Working Mechanism

The equipment and machinery movers are placed & slid under the front or back of the heavy machines or appliances and are rolled through casters to ensure smooth yet secure mobility. Selected front-support machine rollers have a tow eye to attach optional steering bars and a swivel platform allowing equipment on these rollers to turn. On the other hand, rear-support machine rollers have a connection bar that easily adjusts for distributing weight while allowing the rollers to fit under equipment with a wide width range. These rear-support machinery movers have a fixed platform for rectilinear movement.

Frequently Asked Questions

What are the points to consider before unloading the equipment?

Before loading or unloading equipment, operators should ensure the load is properly packaged. For example, if dollies are being used, they must be in good condition and perfectly secured to the load. The dolly itself should be suitable for the equipment to be transported.

How do you lift a dolly upstairs?

For lifting a dolly upstairs, slide the flat base of the hand truck below your item. Now, strap the item safely to the upright support of the hand truck and while gripping the handles firmly, tilt the hand truck towards you for balancing the weight on the wheels. Finally, walk backwards while going upstairs and pulling the hand truck up to one stair at a time.

How much load can you move with a dolly?

You can use furniture dollies when you need to move a dresser, couch, desk or other big equipment. It is commonly used for applications involving heavy and bulky items where a simple utility dolly is not recommended. With these machinery movers, you can typically handle loads up to 132,000 lb.

What is the difference between a dolly and a hand cart?

Dollies come in various designs and sizes for various tasks, but they all have a platform with two axles and four wheels. Carts are ideal for moving several items at one time. Also, dollies are flat, so items need to be lifted onto them.

What is the difference between a machine mover and a rigger?

In industrial and construction operations, a machine mover is suitable for erecting, moving, assembling, aligning, levelling and relocating equipment & machinery and a rigger can move any kind of load.

A rigger is a skilled-craft professional who engages in the lifting and moving of large objects, whereas a machinery mover specializes in machinery and equipment that may additionally require assembly, erection, levelling and aligning.

How often do the machinery movers require industrial maintenance?

Typically, machine movers need industrial maintenance twice a year during slow times.

£ GBPChange Country

£ GBPChange Country