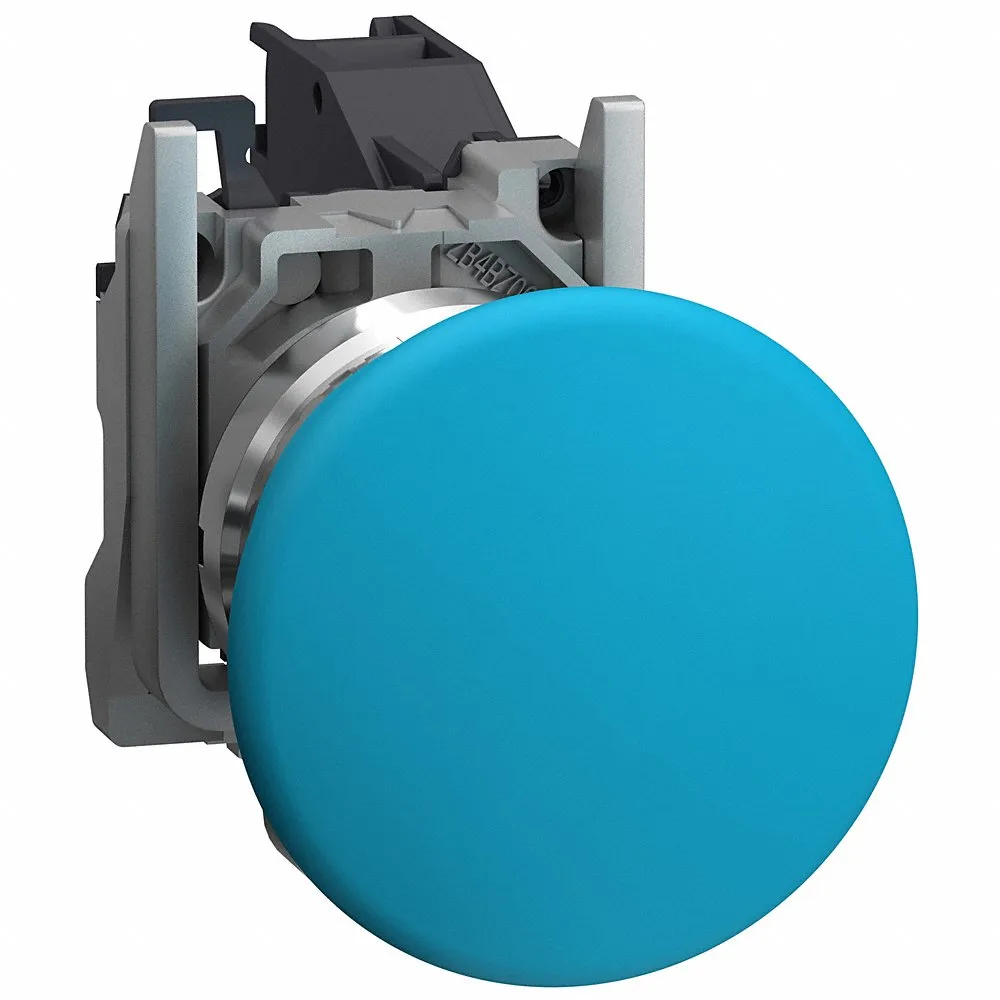

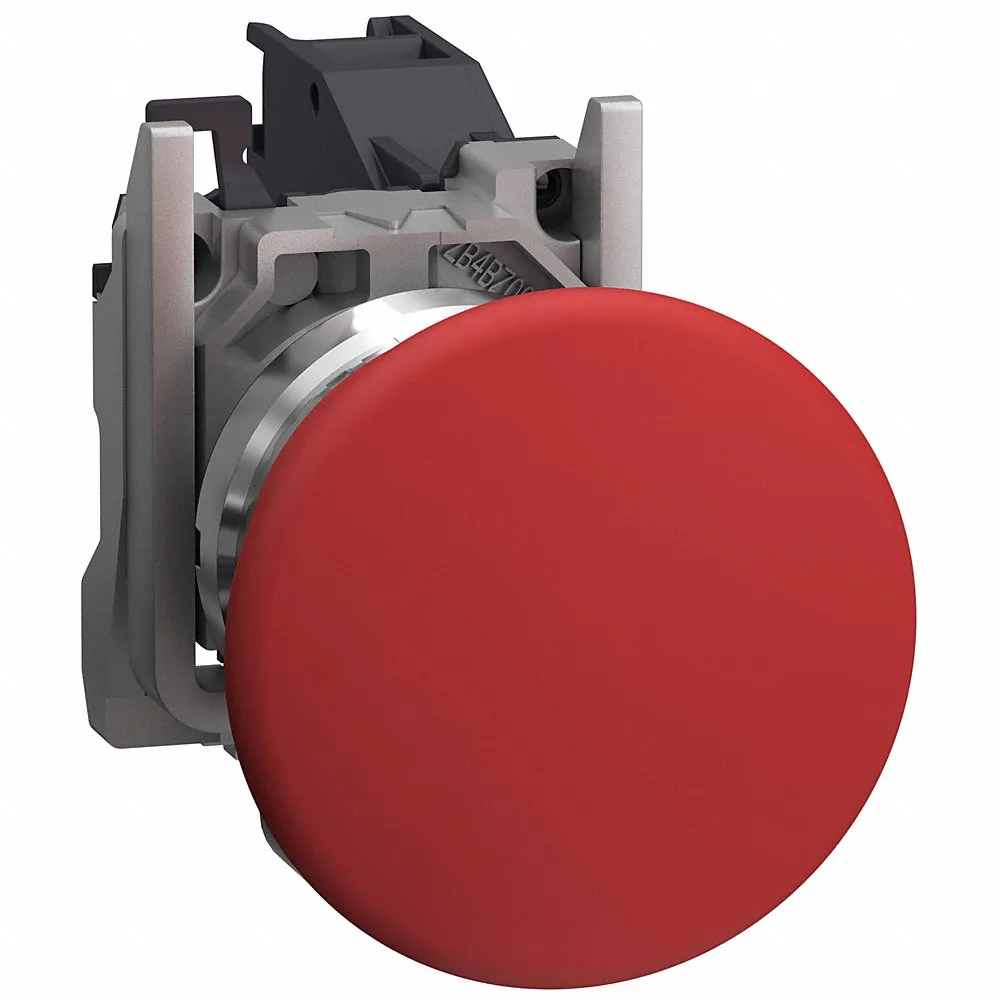

| A | XACA960 | - | - | - | - | - | Button | - | A$ 74.95 | This product can only be shipped in multiples of 10 |

| B | XACA982 | - | - | - | - | - | Button | - | A$ 48.62 | This product can only be shipped in multiples of 10 |

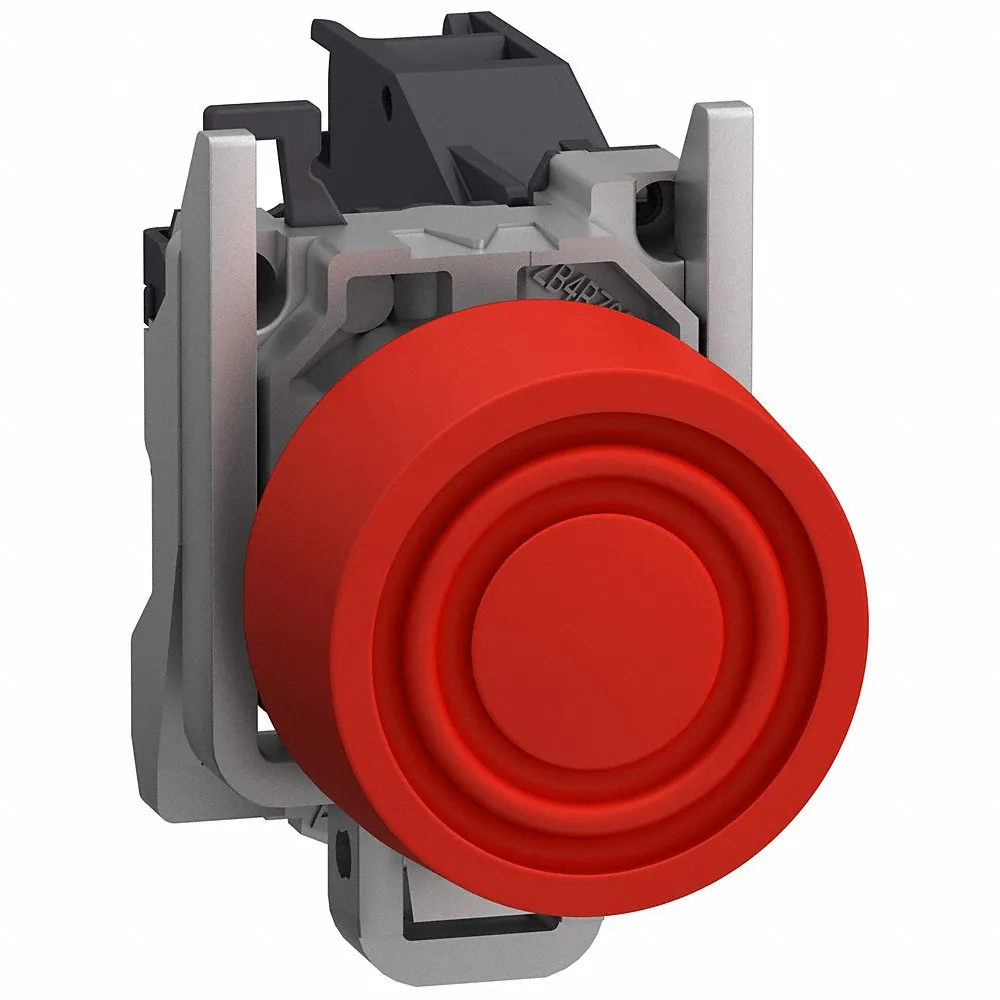

| C | XACB04 | - | - | - | - | - | Button | - | A$ 852.03 | This product can only be shipped in multiples of 10 |

| D | XACA215 | - | - | - | - | - | Button | - | A$ 682.84 | This product can only be shipped in multiples of 10 |

| E | XACS415 | - | - | - | - | - | Contact | - | A$ 74.20 | This product can only be shipped in multiples of 10 |

| F | XACS102 | - | - | - | - | - | Button | - | A$ 76.09 | This product can only be shipped in multiples of 10 |

| G | XACS101 | - | - | - | - | - | Button | - | A$ 68.69 | This product can only be shipped in multiples of 10 |

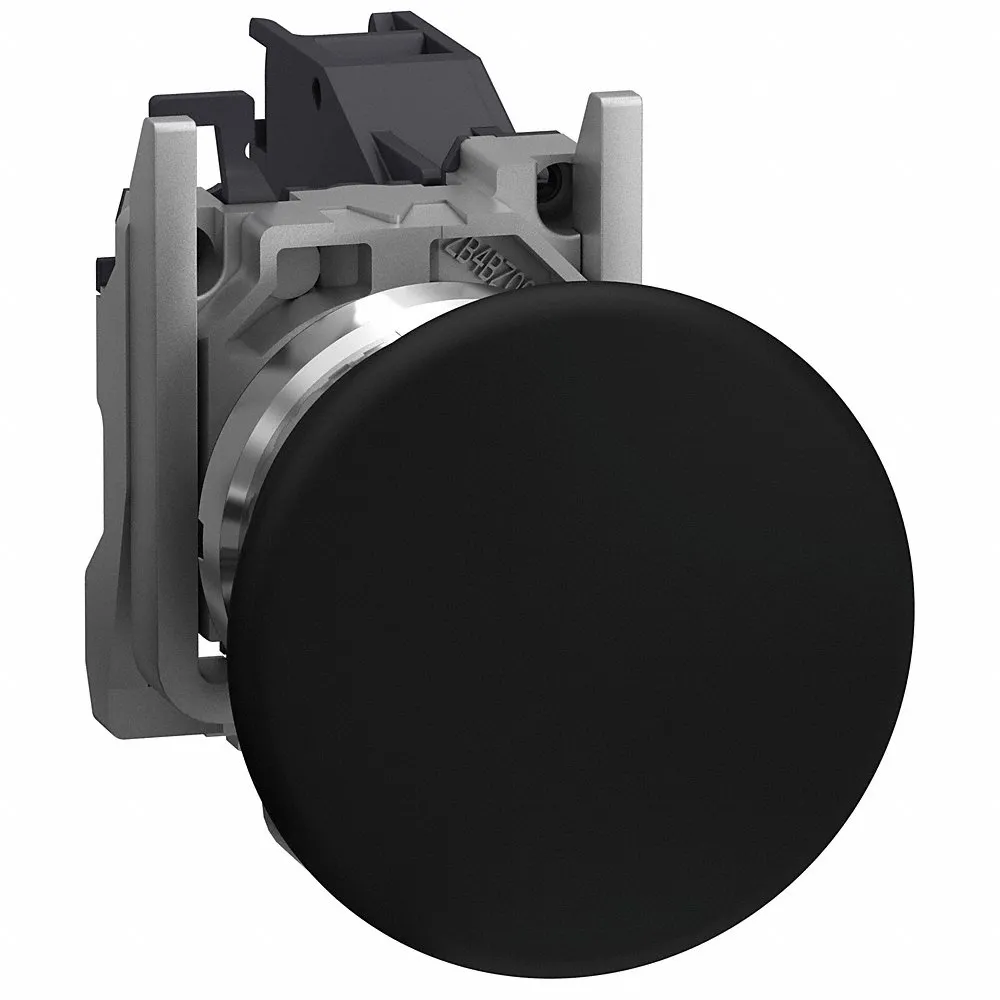

| H | XACA971 | - | - | - | - | - | Button | - | A$ 50.84 | This product can only be shipped in multiples of 10 |

| I | XACA983 | - | - | - | - | - | Button | - | A$ 67.47 | This product can only be shipped in multiples of 10 |

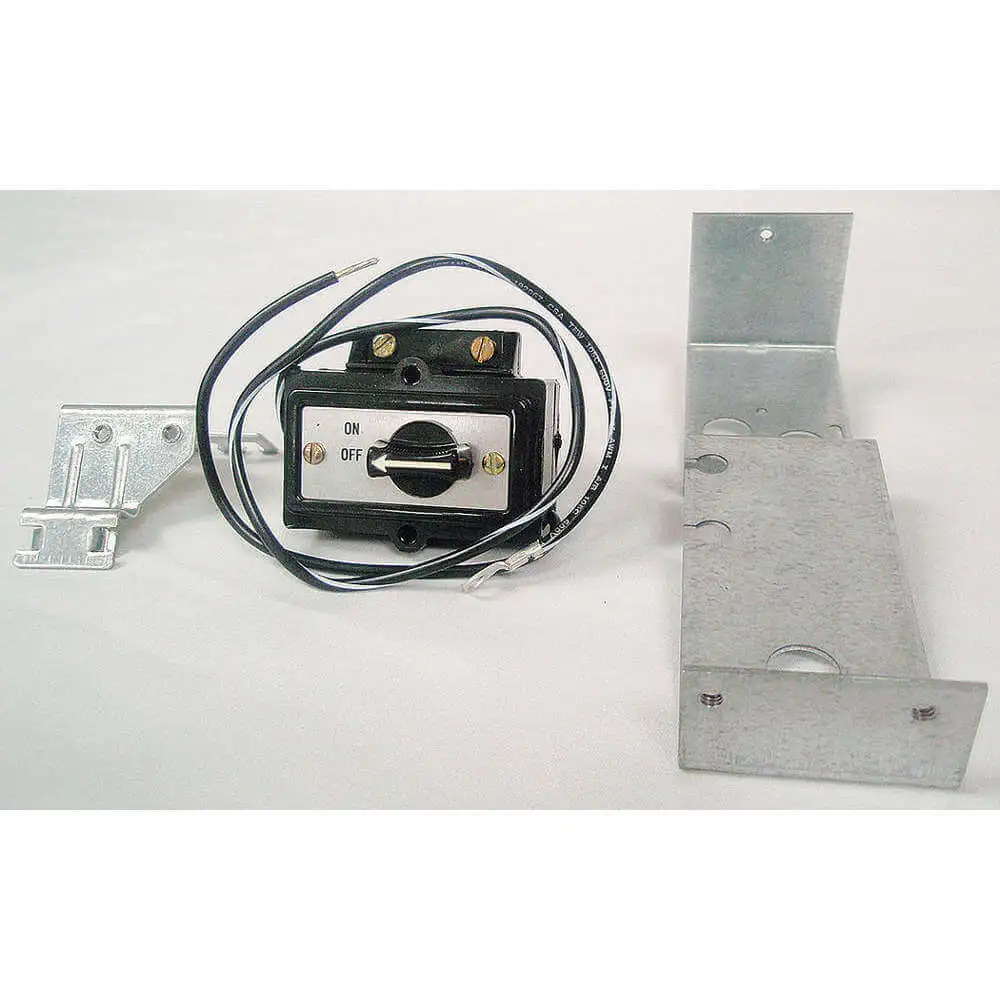

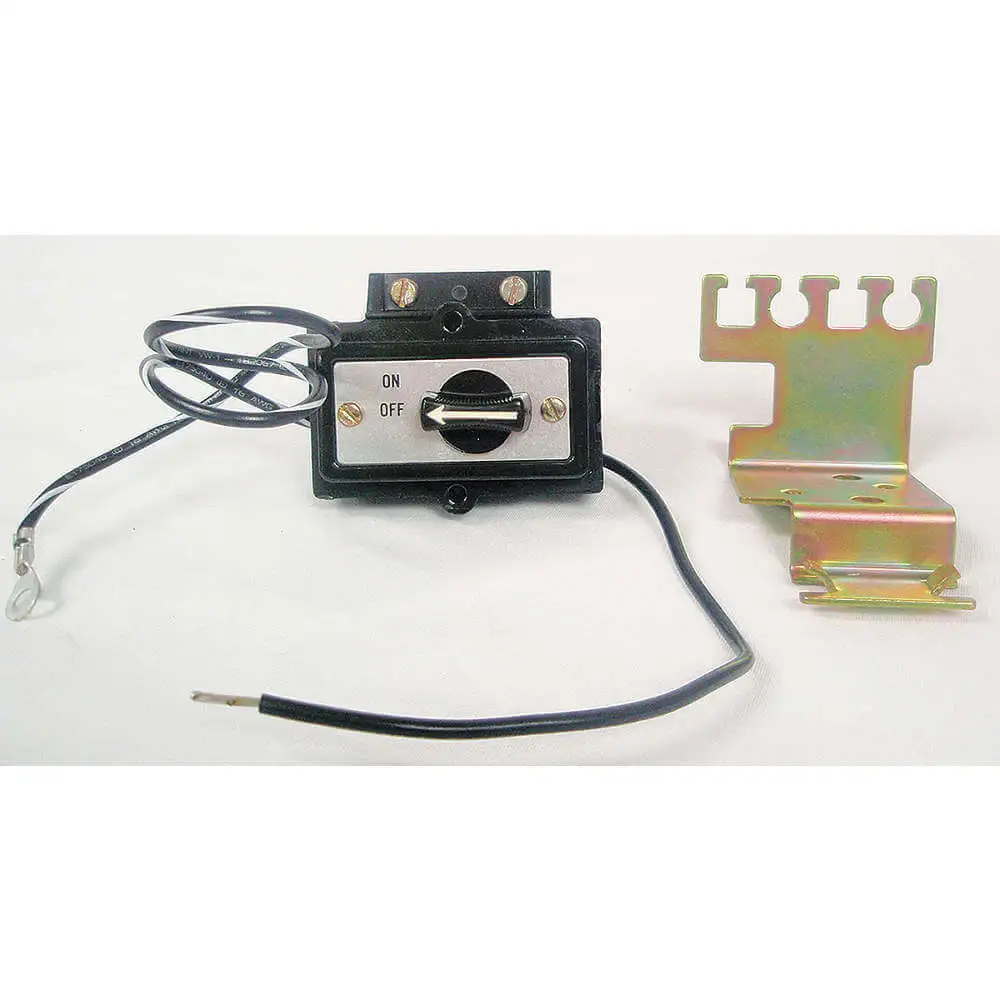

| J | 9001KR12U | - | - | - | - | - | Pendant Push Button | - | A$ 427.71 | This product can only be shipped in multiples of 10 |

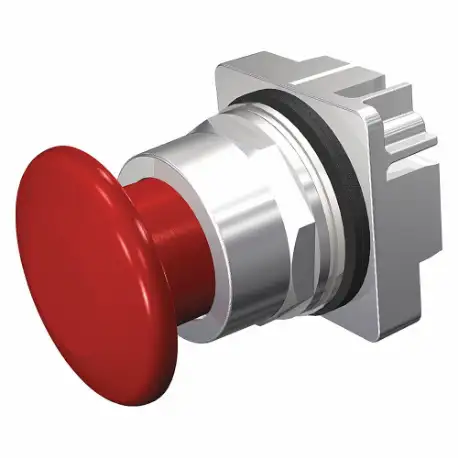

| K | 9001KR11U | Maintained 2 Position, Interlocked | Metal | Chrome Die Cast Aluminum | Multi | Aluminum-Zinc Alloy | Push Button Operator | 1, 2, 3, 3R, 4, 6, 12, 13 | A$ 336.83 | This product can only be shipped in multiples of 10 |

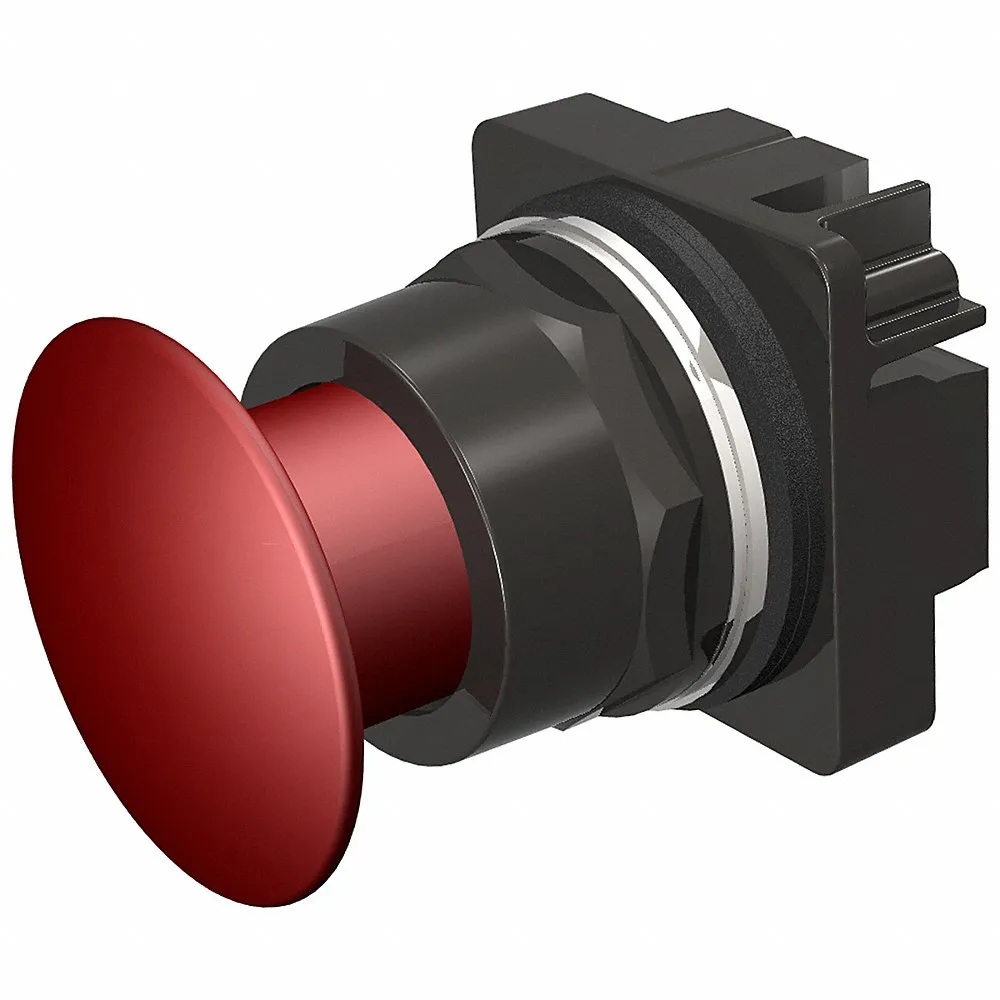

| L | 9001SKR11U | Maintained 2 Position, Interlocked | Plastic | Double-insulated Plastic | Multi | Plastic | Push Button Operator | 1, 2, 3, 3R, 4, 4X, 6, 12, 13 | A$ 336.83 | This product can only be shipped in multiples of 10 |

| M | 9001KR11BR | Maintained 2 Position, Interlocked | Metal | Chrome Die Cast Aluminum | Black/Red | Aluminum-Zinc Alloy | Push Button Operator | 1, 2, 3, 3R, 4, 6, 12, 13 | A$ 283.37 | This product can only be shipped in multiples of 10 |

| N | 9001SKRU3 | Momentary | - | - | - | Plastic | Push Button Operator | 1, 2, 3, 3R, 4, 6, 12, 13 | A$ 1782.73 | This product can only be shipped in multiples of 10 |

£ GBPChange Country

£ GBPChange Country