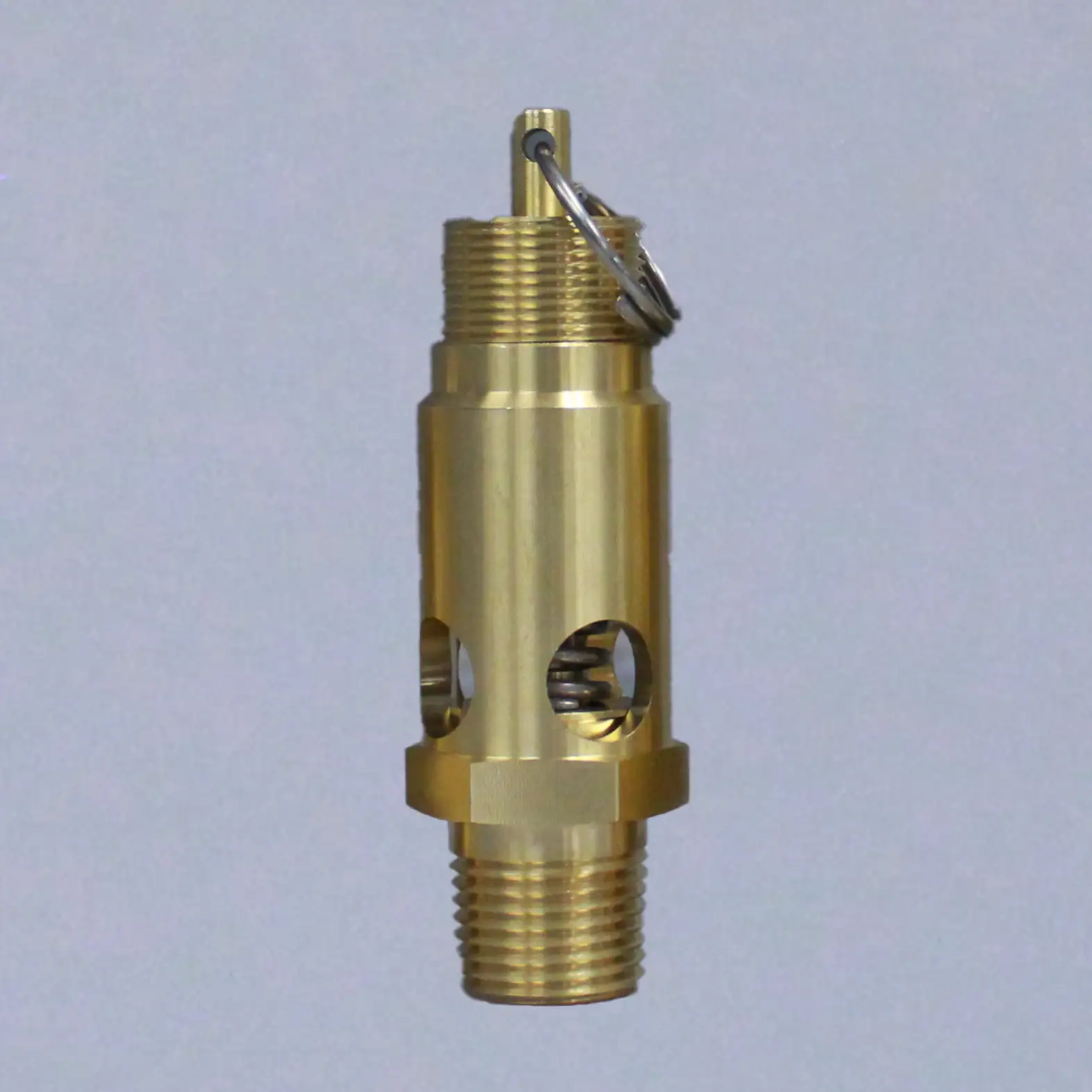

Control Devices Safety Valves

:

- They have brass / brass / stainless steel construction for structural rigidity and durability.

- They offer lead / silicon rubber seal for enhanced and leak free operations.

- These safety valves come with a stainless steel / zinc plated music wire spring to resist corrosion on exposed surfaces.

- These valves come in bubble tight / high capacity / screwed outlet variants as per the user's requirement.

Kingston Pop Safety Valves

:

- They have brass construction for reduced friction and prolonged service life.

- These pop safety valves have an operational temperature range of 250 to 300 degrees F.

- They can be operated at pressures ranging from 1 to 400 PSI.

- These pneumatic safety valves come with a soft seal for leak proof operations.

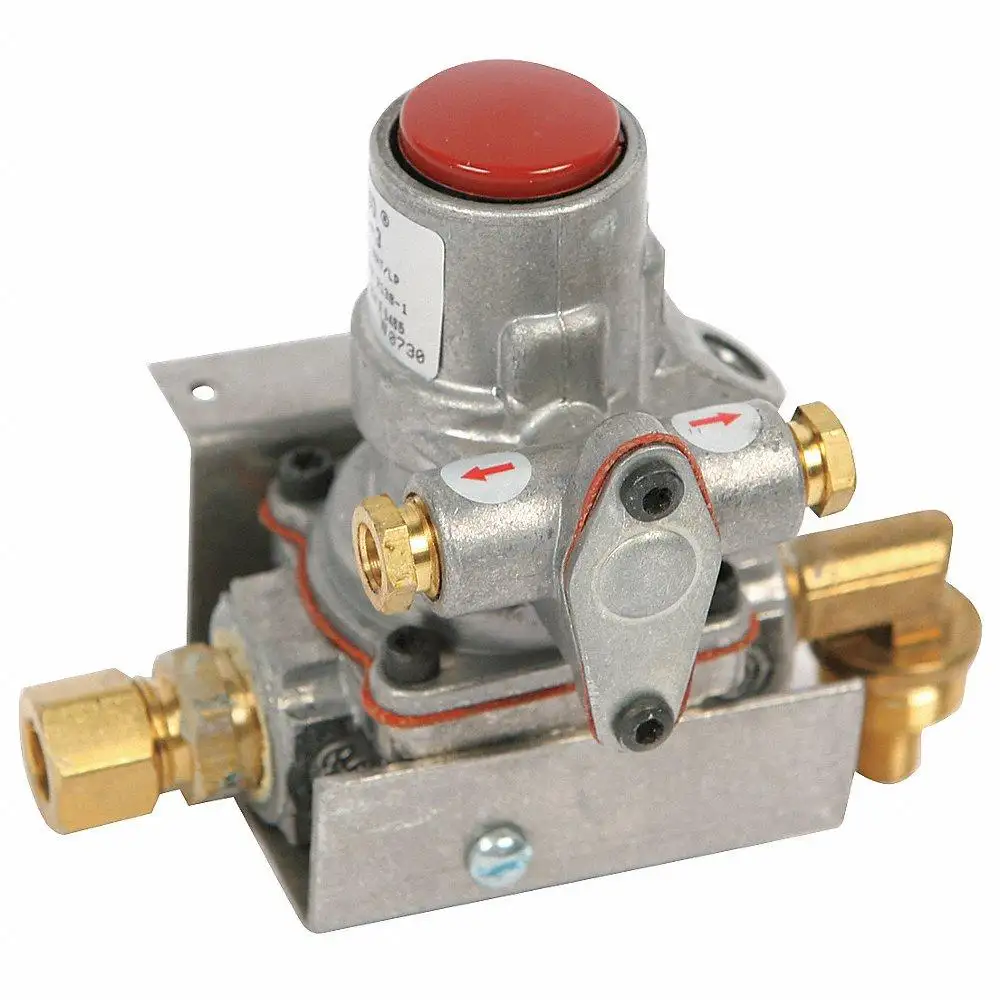

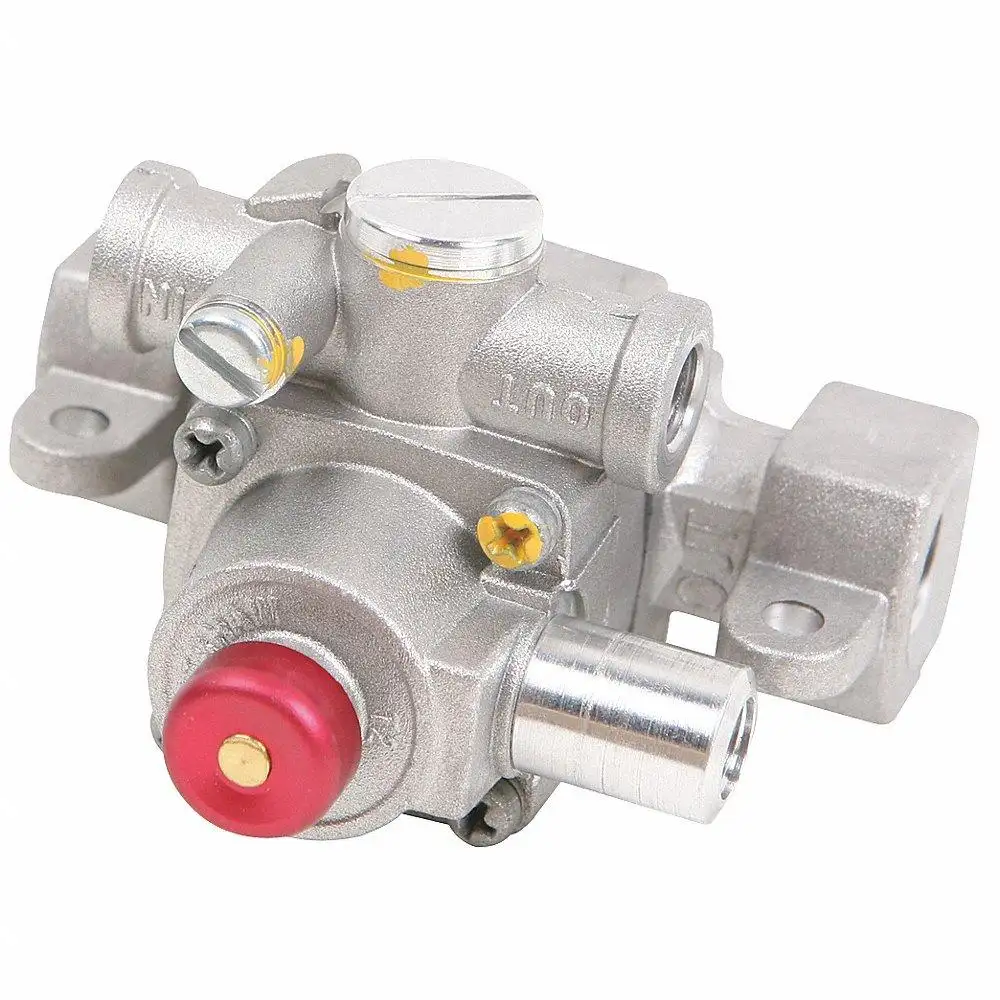

Condrader Safety Valves

:

- They have seat, cap, and piston components made of ASTM B16 brass / ASTM A582 stainless steel for enhanced durability and corrosion resistance.

- These industrial safety valves feature a 302 stainless steel spring for enhanced performance and to withstand moisture.

- They have a 440 stainless steel sealing ball to ensure effective sealing.

- These safety valves come with a shrouded adjustment cap for added protection and safety.

- They offer nickel-plating for enhanced corrosion resistance and an aesthetic, polished appearance.

£ GBPChange Country

£ GBPChange Country