Frequently Asked Questions

How to install push-in rivets?

- Ensure that the rivet gun is working properly by putting the skinny end of the rivet into the rivet gun.

- The threaded end should enter the hole first.

- Place the rivet into the hole while holding the other end into the rivet gun.

- Push the rivet gun until it touches the surface of the material to be fastened.

- Before shooting the rivet gun, rotate it anticlockwise and pull the handle slowly.

- Release the rivet gun's handle and press again.

- Press the rivet gun's handle and pull it away.

- Repeat this process until the material is fully secured.

Can split push-in rivets be painted or coated after installation?

Yes, split push-in rivets can be painted or coated after installation to match the surrounding materials or provide additional protection against corrosion and wear. However, it's essential to ensure that the paint or coating does not interfere with the functionality of the rivets.

How do I choose the right size of split push-in rivets for my application?

When selecting split push-in rivets, consider factors such as the thickness of the materials being joined, the diameter of the mounting holes and the required strength of the connection.

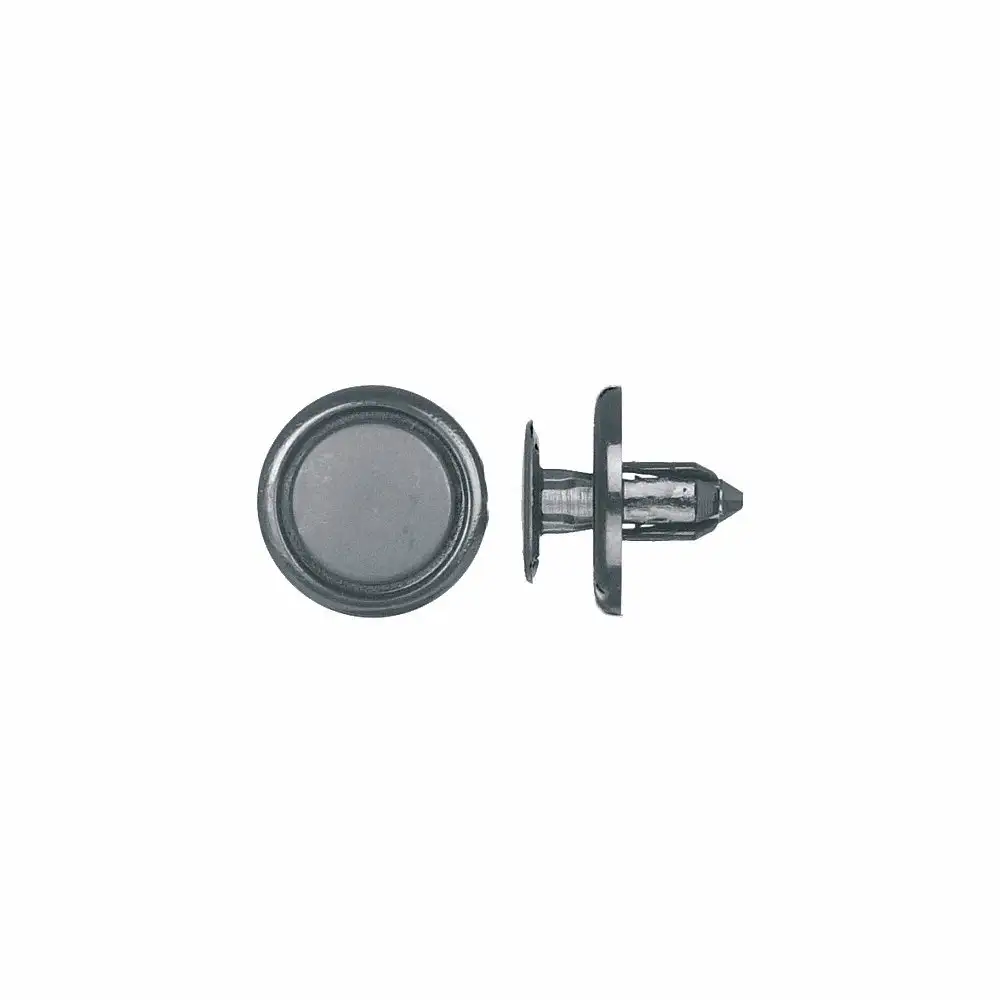

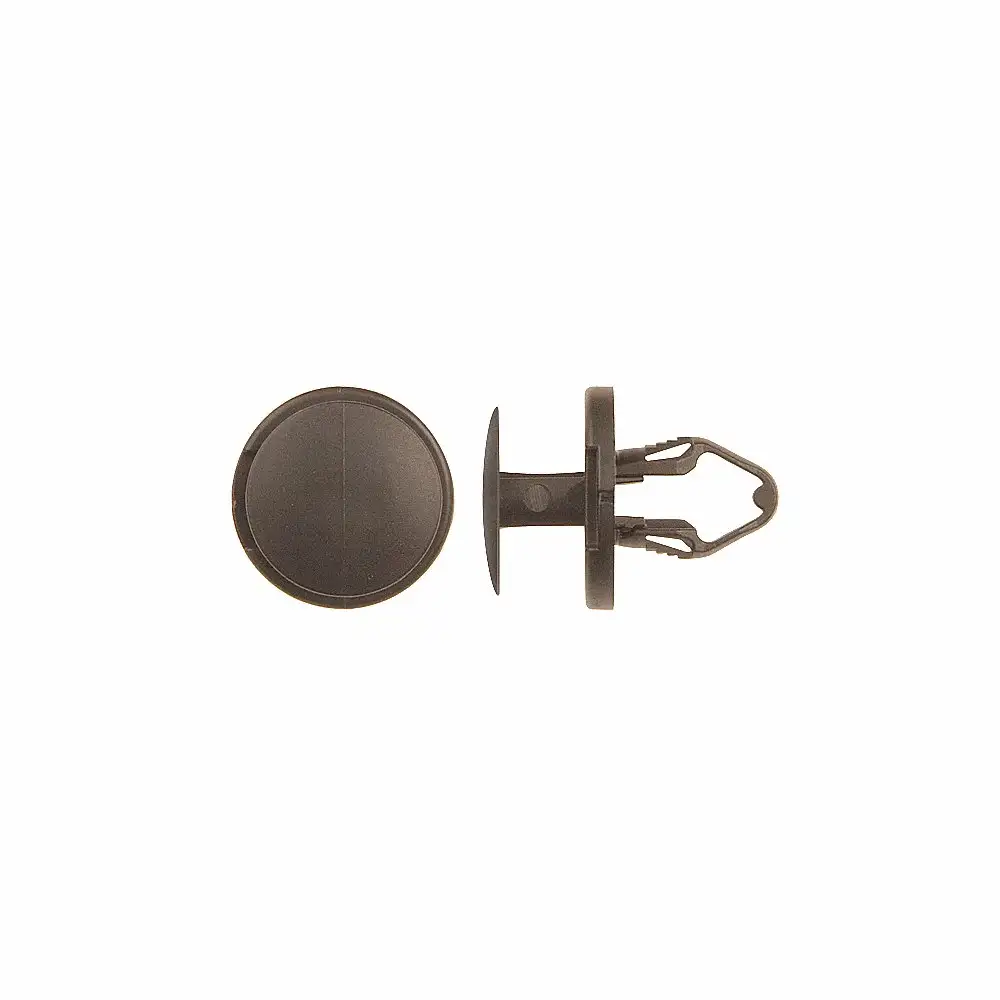

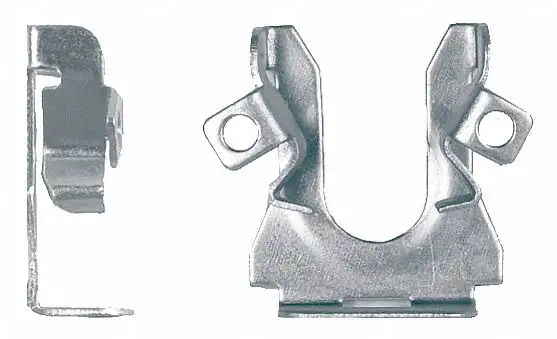

How do split push-in rivets work?

Split push-in rivets work by splitting apart their shanks during installation, which allows them to clamp the mounting surface from the blind side while gripping the exposed surface with their head. This creates a secure and reliable connection between the two surfaces.

£ GBPChange Country

£ GBPChange Country