Frequently Asked Questions

How are retaining spacers installed?

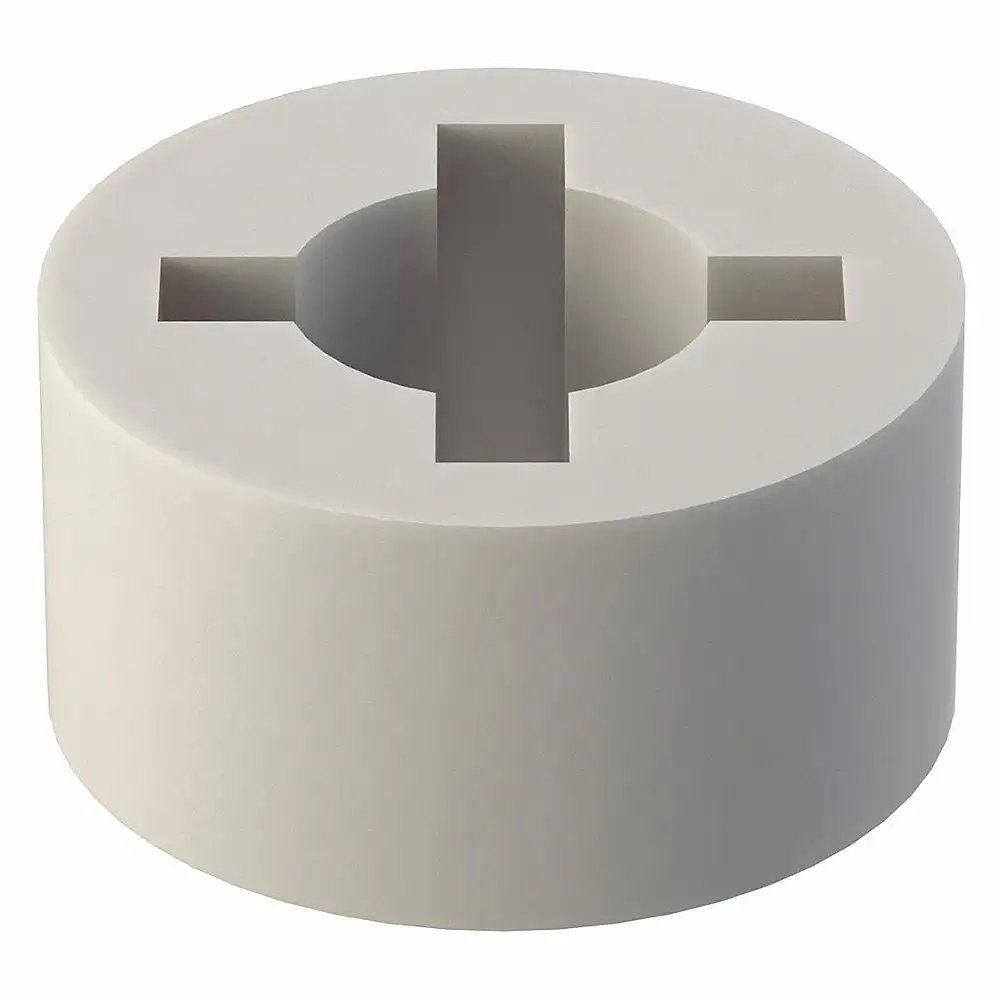

Retaining spacers can be installed by inserting them between the two components that need to be held in place. They may be snapped into place, screwed in or press fit, depending on the specific type of spacer.

What are the factors to consider when selecting a retaining spacer?

Consider the application requirements, the material & dimension of the components, the operating environment and the specific properties needed (strength, durability and resistance to heat or chemicals).

What are the common applications of retaining spacers?

Retaining spacers can be used in automotive & aerospace applications, as well as in electronic and electrical assemblies.

How to ensure safety while using retaining spacers?

When using retaining spacers, follow proper safety protocols and procedures to avoid injury or damage to the assembly. Wear appropriate protective equipment (gloves or eye protection) and ensure that all components are properly installed and secured.

Can these retaining spacers be used in wet or corrosive environments?

These retaining spacers are made of nylon, making them suitable for wet or corrosive environments.

Do these retaining spacers follow the Imperial or Metric system of measurement?

These retaining spacers follow the Imperial system.

£ GBPChange Country

£ GBPChange Country