- Self-drilling screws eliminate punching and pre-drilling processes while joining two metallic or wooden surfaces, and prevent misaligned hole assembly.

- They are divided into mainly 3 parts: the head, the threaded portion and the drill point length

- The head is used to drive in / out the screw from the surface.

- The threaded portion of the screw starts just below the head and is ideal for tapping threads in the workpiece for a secure grip.

- The section below the screw threads has a drill bit shaped design containing the pilot section, flutes & drill point. This unthreaded section is used to remove the drilled material from the pilot hole.

- The threads engage or go inside the material after the drilling is complete.

- Most of these screws have a fully threaded shank or body. However, some screws have a partially threaded shank for protecting them from loosening and prevent breakage / bending due to friction-induced overheating.

Fabory Self Drilling Screws:

- They have plain stainless steel or zinc-plated hardened steel construction to prevent tarnishing.

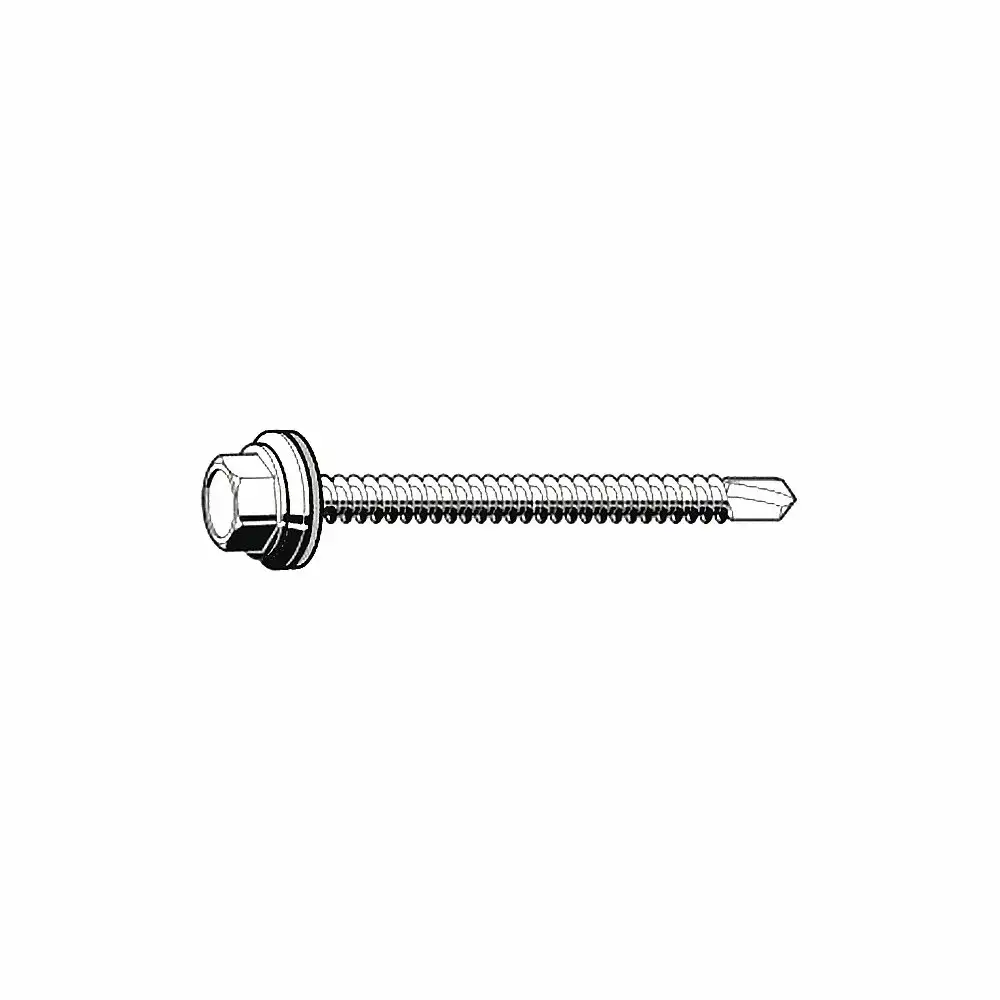

- Selected hex headed self-drilling screws come with a neoprene washer to evenly distribute the load and provide a waterproof seal in roofing / outdoor applications.

Teks Drilling Screws:

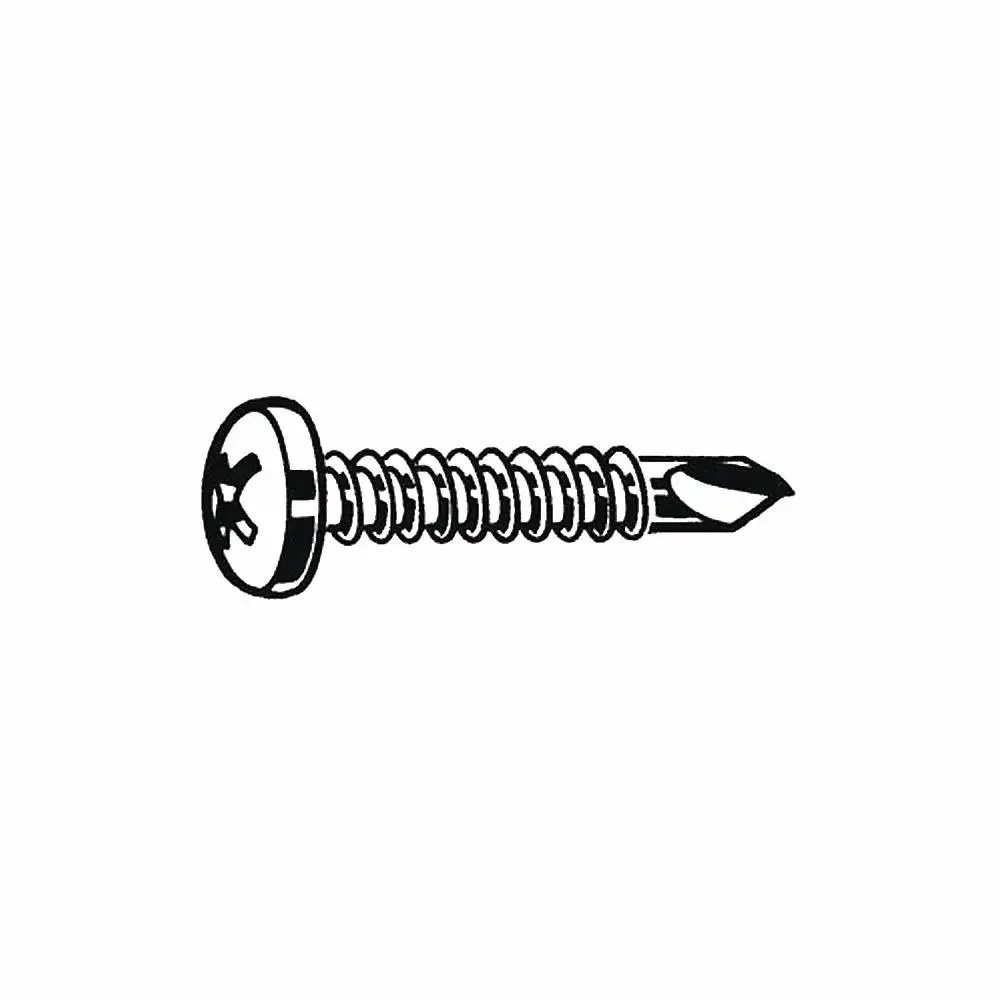

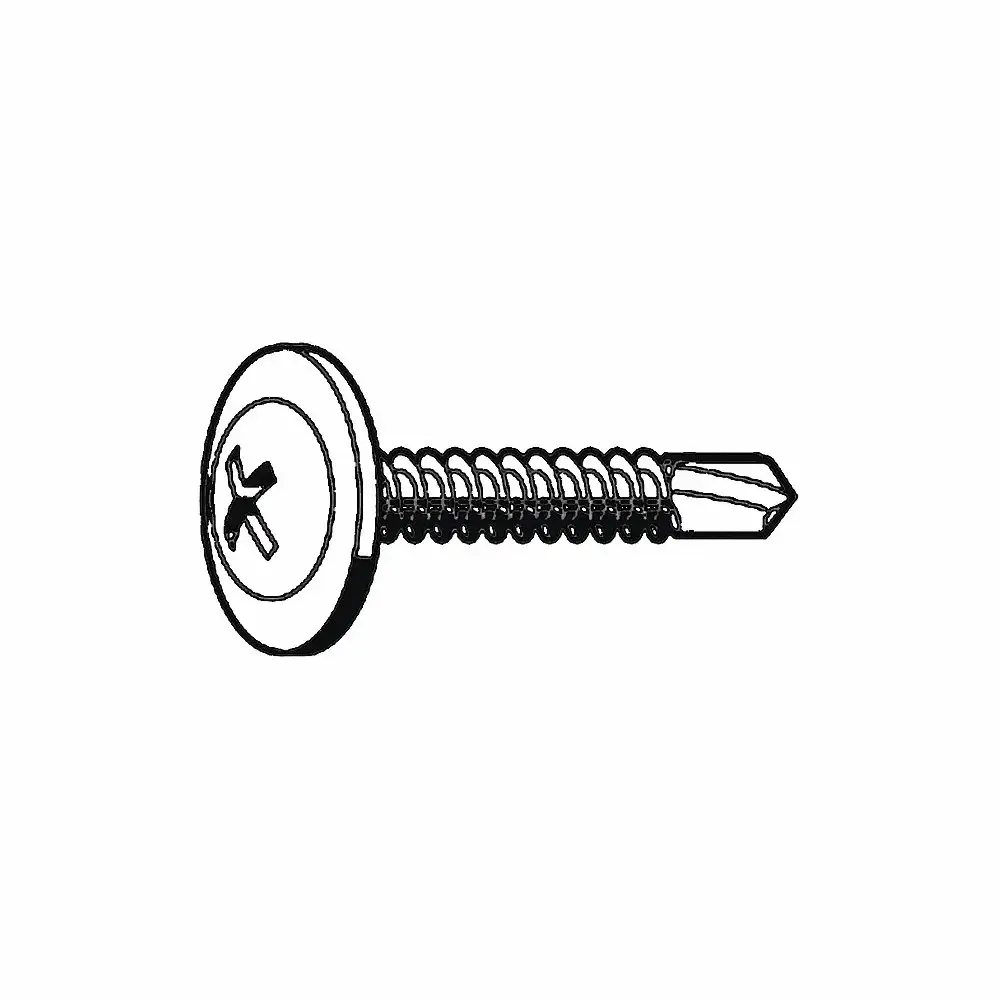

- These Imperial screws have a flat hex washer, a pan or wafer type Philips head, internal hex and Robertson or square drive style for easy installation.

- The steel body is integrated with either Climaseal, Electro-Zinc or Gray Spex finish for preventing bending / breaking under heavy loads.

Snap-Loc Self Drilling Screws:

- These screws have a one-piece design with a hex head and built-in flange washer to reduce the risk of crushing thin metal.

£ GBPChange Country

£ GBPChange Country