- Shoulder screws are installed in pre-tapped holes that require alignment with tolerance. They do not have a tapered shank / pointed tip and hence, can not self-thread into soft materials.

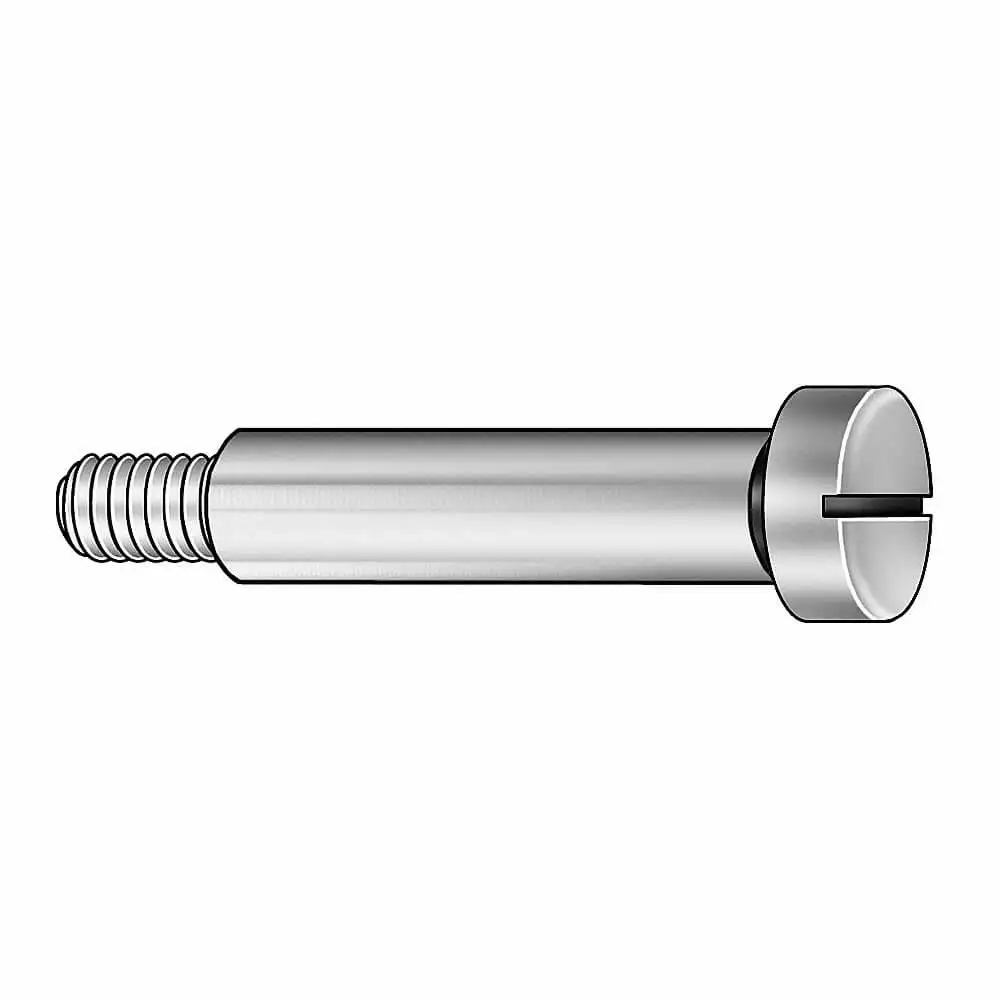

- The head section has the largest diameter that prevents the screw from going too deep and a drive mechanism to apply torque for installation / removal.

- The shoulder is the smooth part, in the middle, that is more than half of the screw length. It allows rotational movement of the bolted workpiece around the screw axis.

- The threaded part of the screw has right- or left-handed helix grooves to accept the mating thread of a nut or tapped hole.

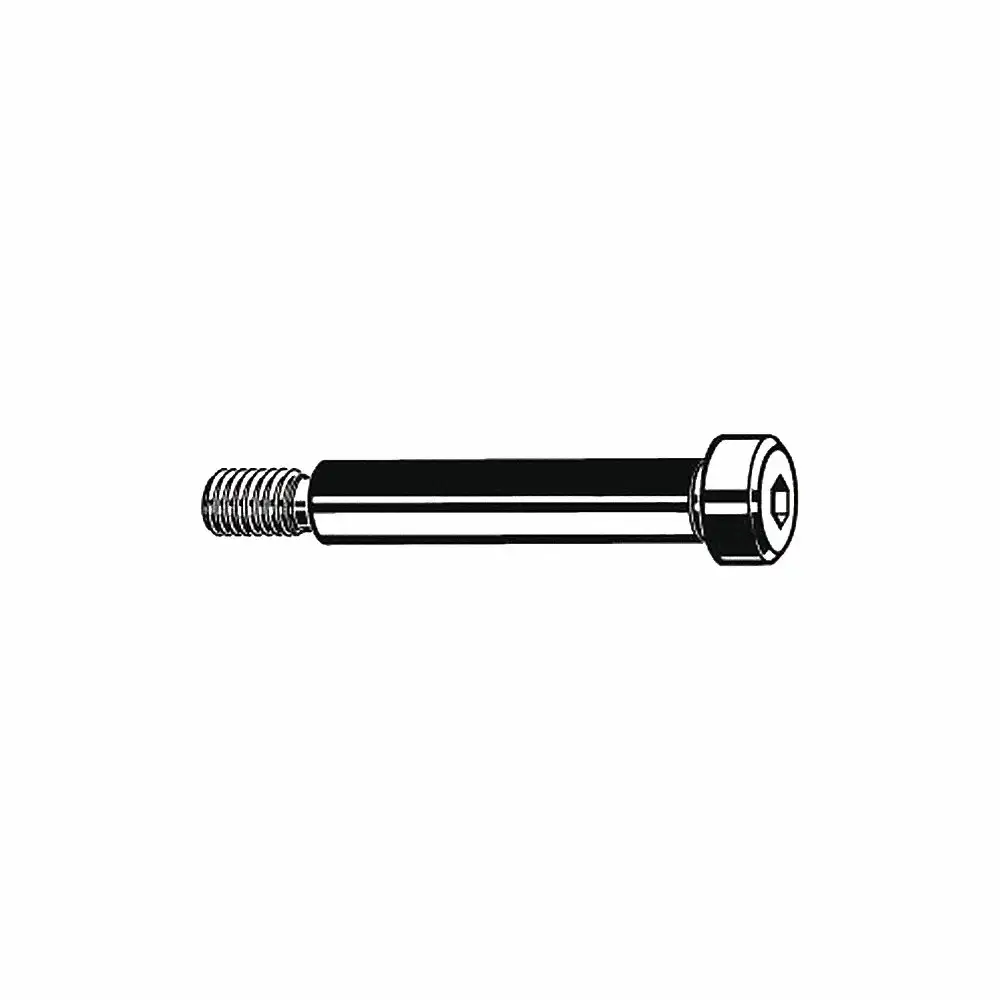

Accurate Manufactured Products Shoulder Screws:

- Users can lengthen the shoulder for more bearing surface by adding washers over their threads and similarly shorten it for better clearance, under the head, by slipping washers over the shoulder.

- Selected models feature AMPG self-locker adhesive that prevents loosening from vibration. It remains dry-to-the-touch until the shearing action of the engaging threads causes the capsules to break, thereby allowing the adhesive to cure. This adhesive permits repeated usage without damaging the threads.

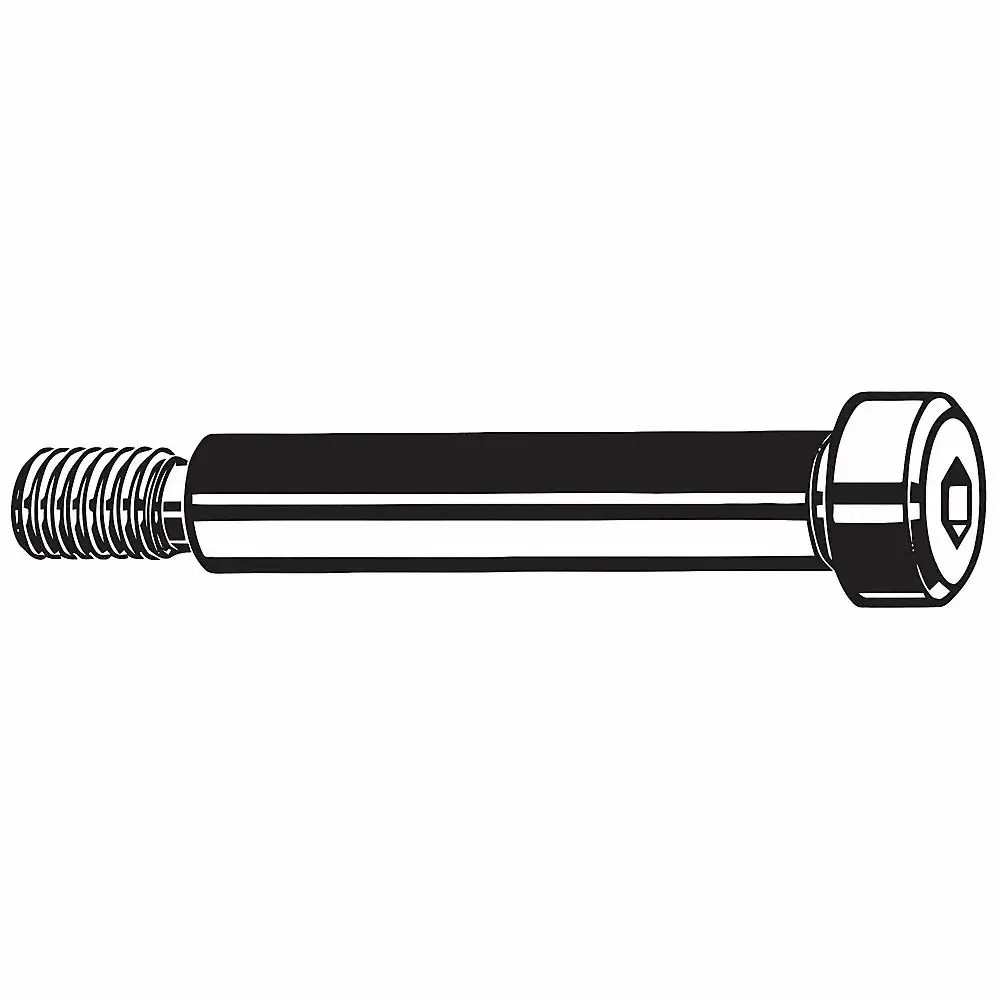

Camcar Shoulder Screws:

- They have a TORX PLUS drive system to prevent tampering and accidental opening.

- Some models are equipped with a locking nylon patch for vibration resistance, once locked / assembled.

£ GBPChange Country

£ GBPChange Country