- Thread-forming screws tightly press their threads into the material for a vibration-resistant assembly.

- Thread-cutting screws are equipped with tapered threads & cutting edges for digging into the material. They generate lesser stress on the material and need lesser driving torque than thread-forming screws.

- Both of these screws are self-tapping for cutting away & removing the surrounding material inside the tapped hole.

- They are divided into 3 parts: the head, the threaded portion and the drill point.

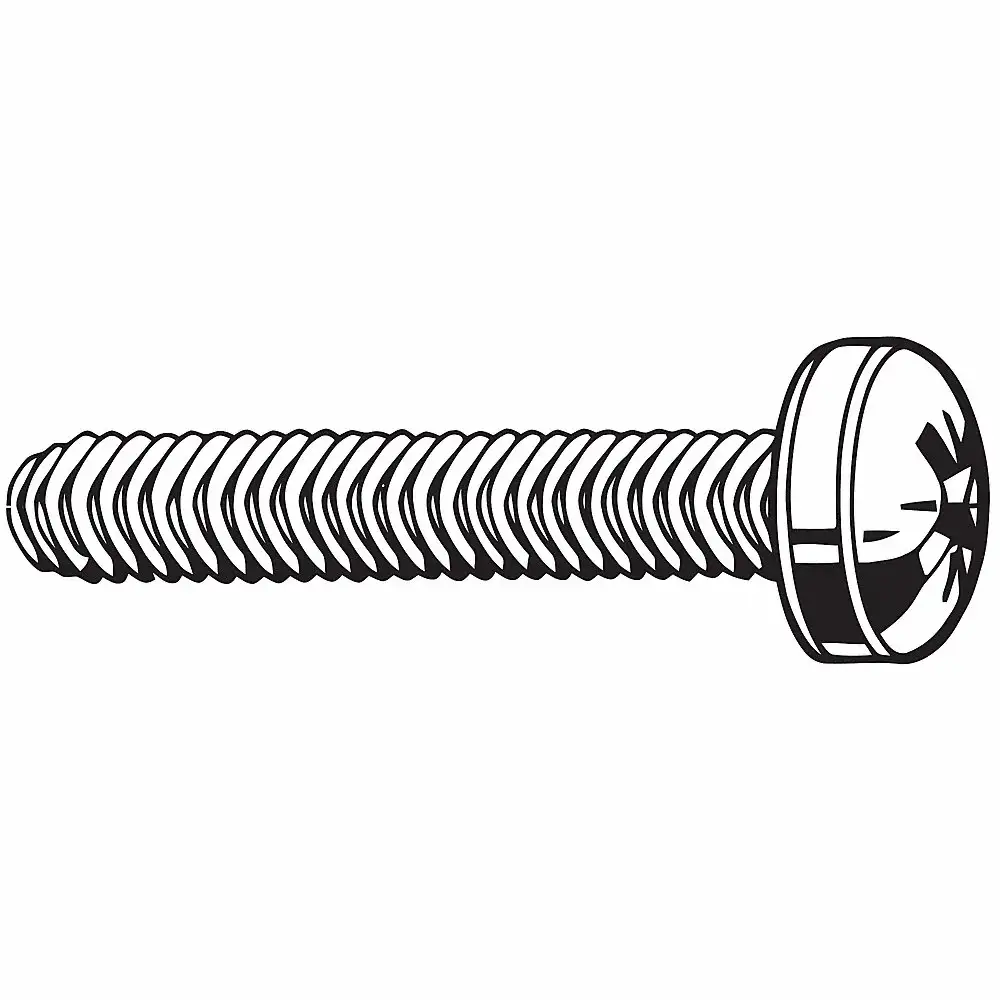

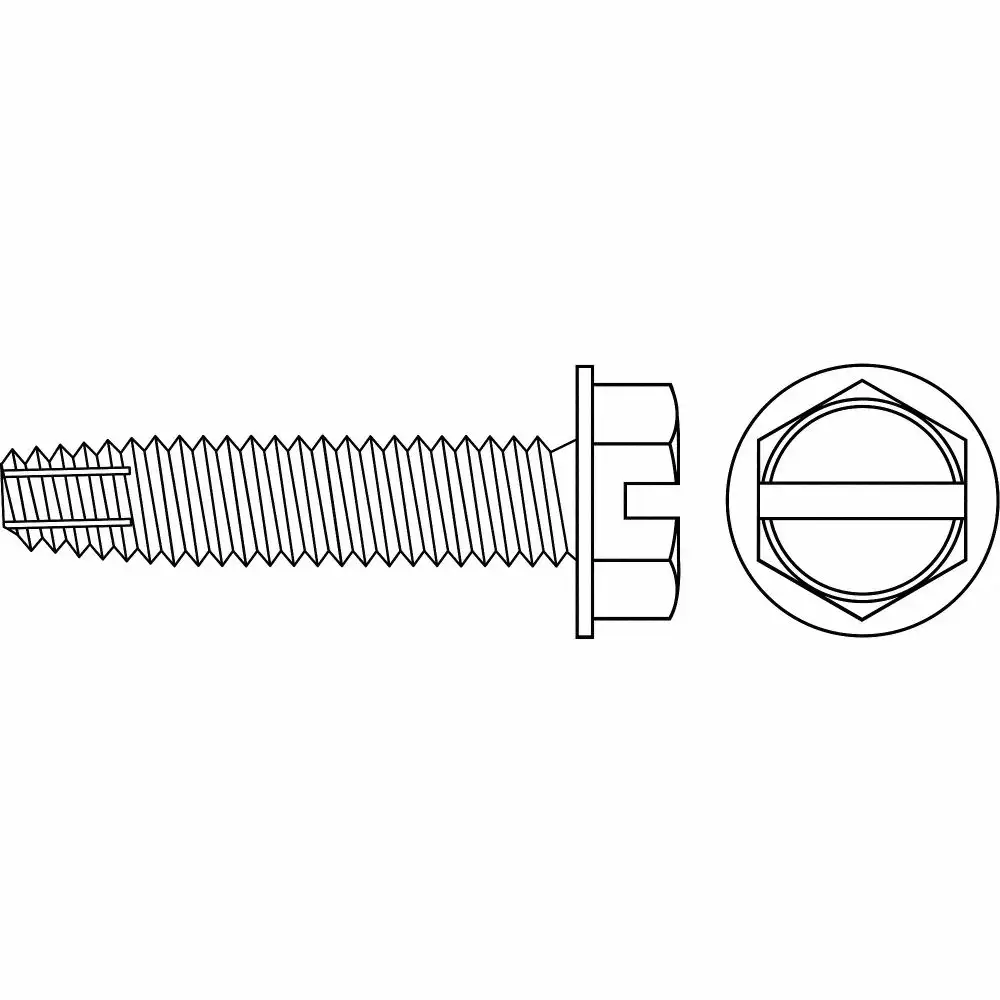

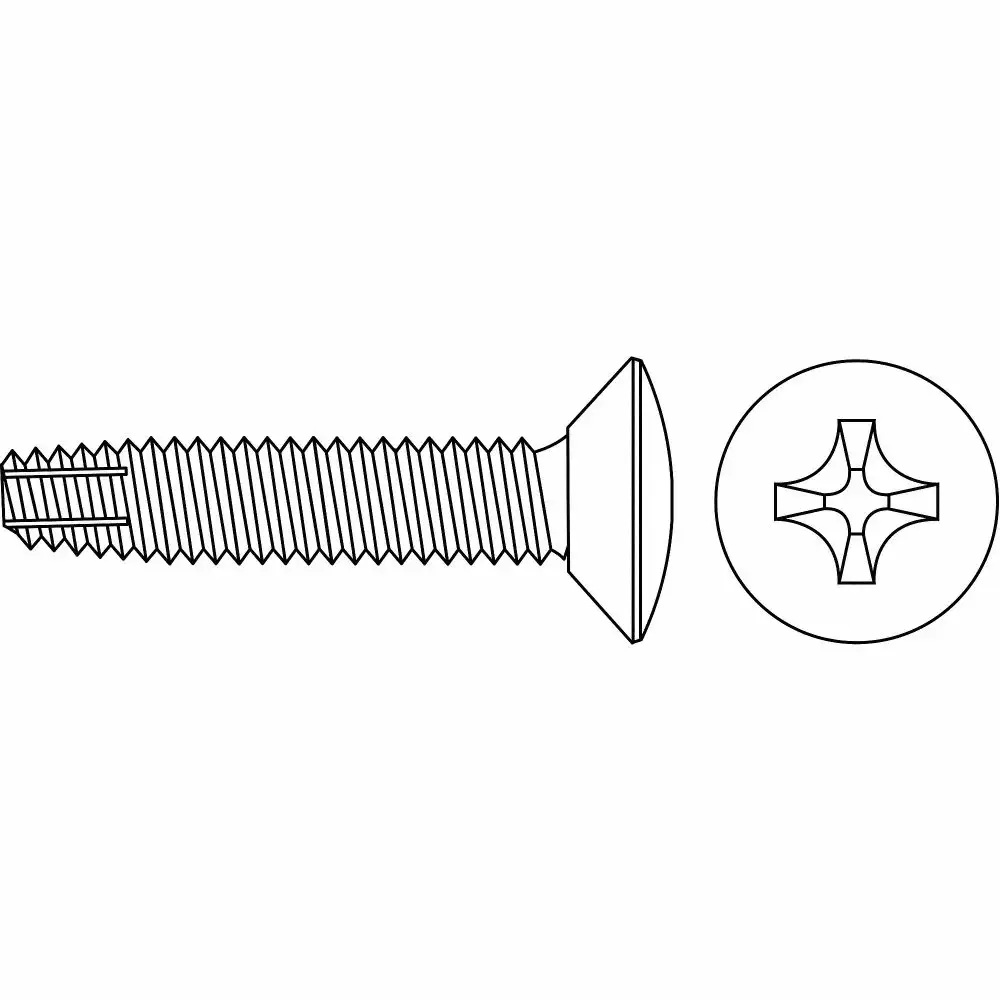

- The head has multiple types of drives for driving the screw in to / out from the surface.

- The threaded portion starts just below the head and is ideal for forming / cutting threads in the workpiece for a secure grip.

- The section below the threads has numerous tapping screw end designs for removing chipped material and improving product performance.

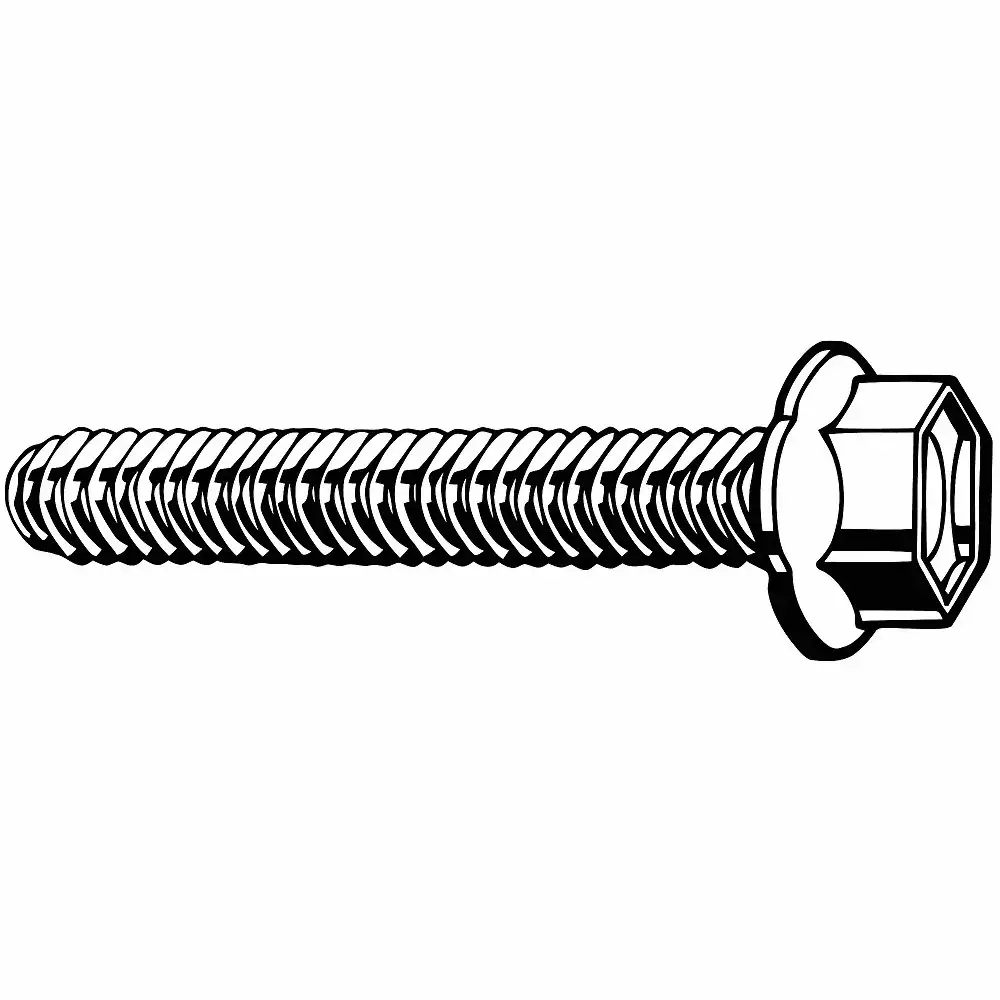

- Selected screws come with a washer to evenly distribute the load and provide a leak-tight seal in outdoor applications.

Grainger Thread-Forming Screws:

- These Imperial screws have a hardened steel body with zinc plating or black oxide finish to prevent bending / breaking / corrosion under harsh conditions.

- Their pan / flat / hex washer head is equipped with Philips / Torx / slotted drives for easy installation & removal.

- Grainger thread-forming screws are available in F & BT screw end styles for specific applications.

Grainger Thread-Cutting Screws:

- These Imperial screws have a pan / flat / hex washer head with Philips / slotted drives for easy installation.

- Their steel / hardened steel body features zinc plating or clear zinc finish to prevent corrosion under harsh environmental conditions.

- Thread-cutting screws can be easily removed and are ideal for applications / workpieces that require periodic maintenance.

£ GBPChange Country

£ GBPChange Country