Frequently Asked Questions

How to repair threaded holes using these kits?

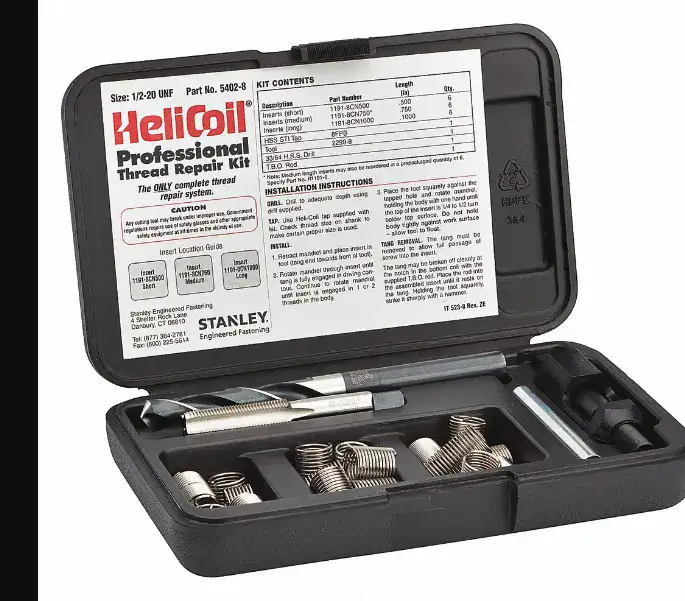

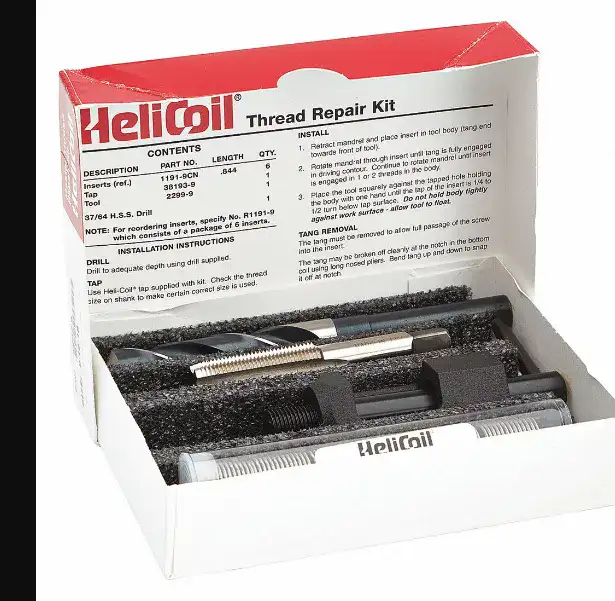

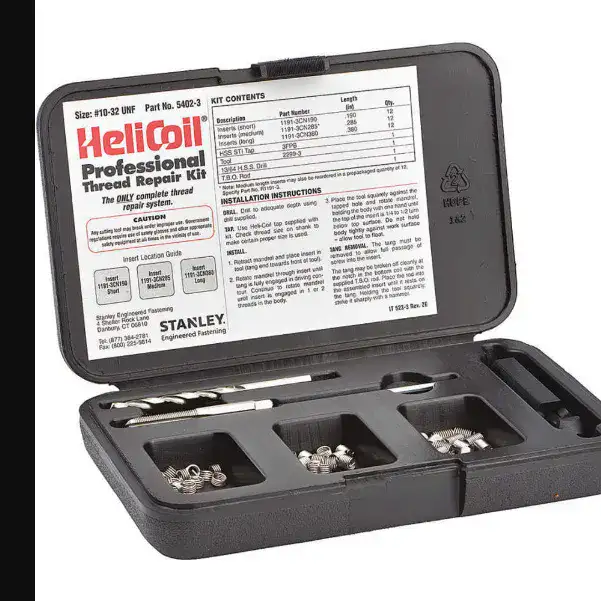

- Select a drill according to the length of the insert to drill out the damaged threading up to the required depth.

- Use an appropriately sized tap to re-thread the drilled-out hole in the material.

- Select a threaded insert from the helical thread repair kit and use the supplied installation tool to wind the insert into the hole.

- Use the tang break-off rod or punch to remove the tang and allow free passage of bolts. Large-sized holes or spark plug inserts require long-nose pliers to bend the tang in & out alternately until the tang breaks free.

- The repaired threaded hole is ready for fastening applications using fasteners such as bolts.

What accessories can be used with Helicoil thread repair kits?

Raptor Supplies offers locking thread inserts that lock a fastener once installed and prevent accidental rotational spin-outs due to vibration or torque. We also supply replacement free running inserts and compatible Helicoil repair tools for replacing old, worn-out or damaged parts.

Can Helicoil inserts be removed once installed?

Yes, Helicoil offers Metric free-running tangless removal tools that attach to Helicoil inserts & unwind them in the direction opposite to that of installation.

Why are Helicoil inserts larger in diameter than the tapped hole before installation?

The diameter of Helicoil thread inserts is slightly larger than the tapped hole as the installation tool reduces the diameter of the leading coil when it applies torque to the insert's tang. This allows the insert to enter the tapped hole. After installing Helicoil threaded insert, its high tensile stainless steel coil acts like a spring and expands outward onto the metallic material for a strong anchoring connection.

How to repair a broken thread?

- Determine the thread size using a thread template.

- Clamp the suitable core drill bit.

- Oil the core drill bit with thread-cutting fluid.

- Use the core drill to remove the damaged thread.

- Clamp the suitable tap in a tap wrench.

- Oil the tap with thread-cutting fluid.

- Cut the thread for thread inserts.

- Select an appropriate thread insert and drive it in using a screw-in tool.

- Disintegrate the tang with the tang breaker.

- The new thread is ready for use.

£ GBPChange Country

£ GBPChange Country